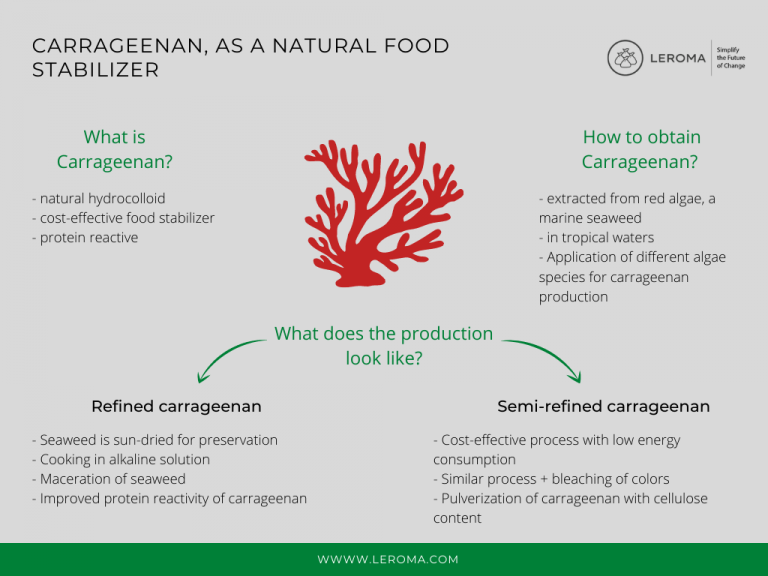

After harvesting the seaweed is sundried for preservation.

In the first production step the seaweed is washed to remove adhering salts and sand.

The seaweed is then cooked in an alkaline (sodium hydroxide or calcium hydroxide) solution. In this step, the seaweed is macerated and the carrageenan is dissolved in the extraction solution. Additionally, the chemical reaction that enhances the gelling properties and protein reactivity of the carrageenan happens at this stage.

Clarification and Concentration

Seaweed residues that are not dissolved are separated from the extraction mixture by filtration or centrifugation. In this stage, the solution already contains around 1-2% of carrageenan. The filtered carrageenan solution is concentrated to final carrageenan concentration of around 2-3%.

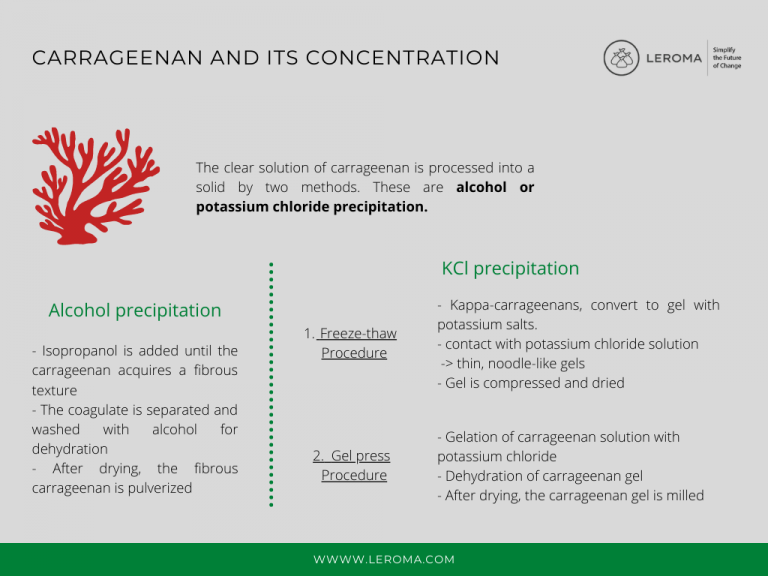

The processor now has a clear solution of carrageenan and there are two methods for recovering it as a solid – either by Alcohol or KCl Precipitation.

1. Alcohol Precipitation

In the alcohol method, isopropanol is added until all the carrageenan in the solution is precipitated as a fibrous coagulum.

The coagulum is then separated using a centrifuge or screen followed by mechanical pressing to remove excess solvent and washed with more alcohol to dehydrate it further. Following the final wash the coagulum is dried and the alcohol recycled.

The fibrous carrageenan from the dryer is then ground to a powder and sifted to the specified particle size.

2. KCl Precipitation

a) Freeze-Thaw process

The KCl method relies on the ability of kappa carrageenans to form a gel with potassium salts.

For the freeze-thaw process the carrageenan solution is forced through fine holes into a potassium chloride solution. Once in contact with potassium chloride, thin noodle-like gels are formed. These gels are collected, washed with more potassium chloride and pressed to remove liquid and then frozen.

When allowed to thaw, water separates from the gel (syneresis), the carrageenan gel is washed again with potassium chloride, chopped and dried in a hot air dryer.

In this second method Potassium Chloride is added to make the carrageenan solution gel in tanks of several hundred liters. The gels are wrapped in cloth and water is forced out of the gel by applying pressure to it. After squeezing for several hours the predried gel is chopped, dried in a hot air dryer and milled to an appropriate particle size.

Production process “semi-Refined Carrageenan” PES (processed Eucheuma seaweed) E 407a

This lower cost process consumes much less energy. The first steps are similar. But during alkaline cooking the seaweed cell structure is kept intact. Afterwards the seaweed is bleached with either Hypochloride or Peroxide to remove pigments and dark colour and the subsequent washing removes bleaching agent, proteins and undesired components. What remains is carrageenan and cell walls consisting of cellulose which will be dried and ground to a powder. This resulting “semirefined” carrageenan powder contains up to 15% cellulose and therefore cannot produce transparent gels, but opaque gels.

kappa, kappa2, iota and lambda. All show different performance in terms of gel strength, texture, solubility and protein reactivity.

Carrageenan is suitable as an additive for many products, with its high milk protein reactivity standing out in particular, enabling its use in numerous milk-based products. Among commercially available hydrocolloids, only carrageenan has the unique milk protein reactivity that works at a dosage as low as 150 parts per million (0.015%) in dairy beverages. It offers an unparalleled cost-effective option and exceptional functionality. Because of its good interaction with the milk protein casein, carrageenan is an excellent stabilizer for processed cheese and whipped cream, for example, and for aerated dairy products because of its film-forming ability. Among the three carrageenan types (kappa, iota, lambda), kappa carrageenan possesses the highest synergism. Carrageenan reacts with all the casein proteins (alpha, beta and kappa) but kappa casein-carrageenan interaction exhibits the strongest bond.

Carrageenan is also used in small doses in processed meats, but brings great benefits to the overall properties of the final product. Due to its excellent water-binding ability, carrageenan effectively retains water in highly expanded meat products, prevents dripping and thawing losses, and complements the pH-dependent water-binding ability of ingredients such as salt and phosphate. It also improves sliceability and supports meat-like texture in reconstituted meat products, among other benefits.

The water-binding capacity also makes carrageenan an effective thickener and stabilizer for sauces.

Flans and puddings benefit from the versatility that carrageenan offers as a gelling agent in both hot- and cold-filled systems. In particular, lambda-carrageenan is highly soluble both hot and cold. Carrageenan is also an effective beer clarifying agent as it reacts with the haze-causing protein in the wort at a very minimal dosage. Furthermore, carrageenan is useful as a stabilizer in toothpaste due to its ability to provide non-stringiness, which is important both in the high speed production line and for the consumers who prefer non-tailing toothpaste.

In addition to the examples listed, there are many more food and non-food applications for carrageenan. We thank the company Marcel Trading Corporation (Marcel Carrageenan), which provided us with the information for this article. Of course, you can also find the products of Marcel Carrageenan on the platform of LEROMA.

Let’s simplify the future of change!