Textilien, Designerlampen und Kunststoffe aus Orangenschalen

Weltweit werden etwa 78 Millionen Tonnen Orangen produziert. In Europa kommen die meisten Orangen aus Italien, Spanien und Griechenland. Bei der Lebensmittelproduktion von Saft oder Marmeladen bleiben enorme Mengen an Orangenschalen übrig und werden entsorgt. Allein in Italien werden jährlich etwa 1 Mio. Tonnen Zitrusfruchtschalen entsorgt.

Um nachhaltig zu wirtschaften und die Schalen als Rohstoff weiter zu verarbeiten, gibt es eine Reihe an Möglichkeiten. Eine gängige und bekannte Methode ist die Herstellung von Orangen-Reinigern, die mit dem frischen Duft der

ätherischen Öle aus den Schalen einen angenehmen Geruch im Raum verbreiten. Außerdem hilft das Orangenöl dabei, Kalkablagerungen oder Fettflecken zu entfernen. Die Reinigungsmittel sind aufgrund ihrer natürlichen Wirkstoffe sehr beliebt, denn diese sind einerseits gesundheitlich unbedenklich und darüber hinaus besser für die Umwelt, da sie keine ätzenden Chemikalien enthalten.

Neben den ätherischen Ölen kann auch das Pektin aus der Schale gewonnen werden. Dieses befindet sich vor allem in der weißen Haut der Orangenschale. Es besteht aus pflanzlichen Polysacchariden und ist auch in vielen anderen Früchten enthalten.

Pektin wird häufig in Marmeladen als natürliches und pflanzliches Geliermittel eingesetzt. Produzenten von Orangen können mit der Weitergabe der Schalen die Entsorgungskosten sparen und durch die Wiederverwendung in anderen Industrien eine nachhaltige Kreislaufwirtschaft anstreben.

Einige Unternehmen haben sich andere innovative Methoden überlegt, um die großen Mengen Schalen weiter zu verwerten und so nachhaltiger zu wirtschaften.

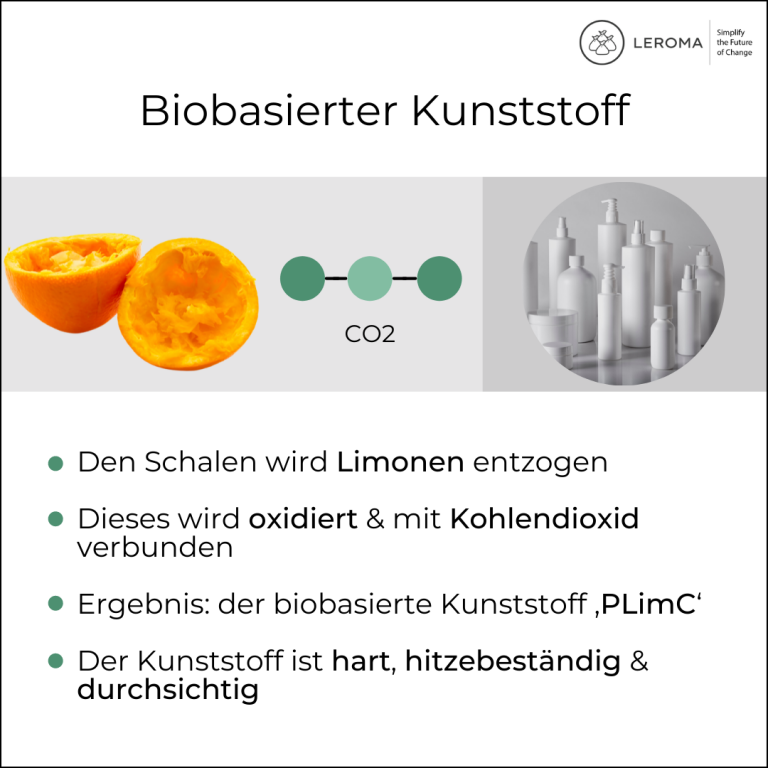

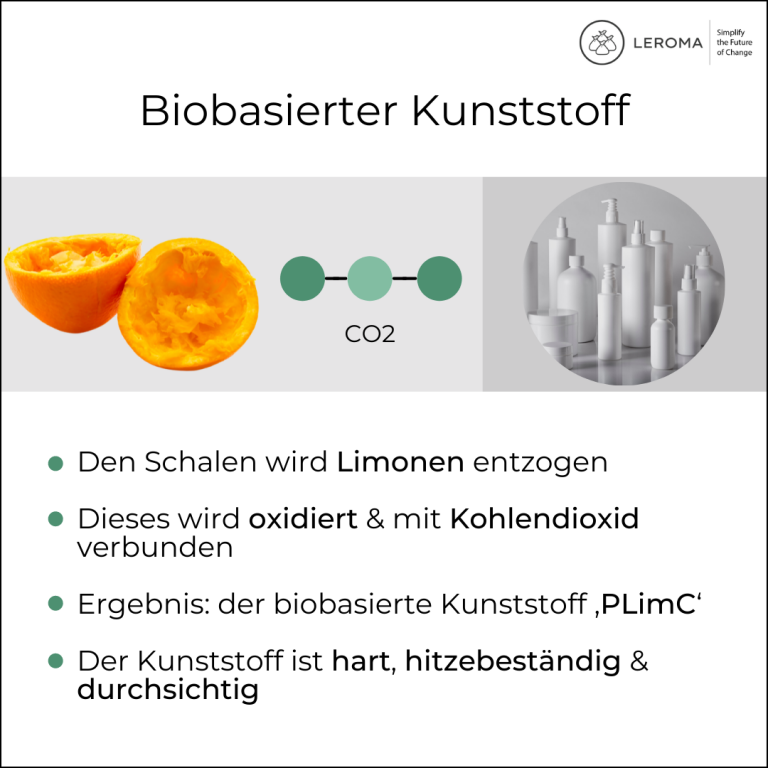

Biobasierte Kunststoffe und Verpackungsmaterial aus Orangenschalen

Aus den Schalen der Orange können biobasierte Kunststoffe und Verpackungsmaterial hergestellt werden. Die Verpackungen bestehen dann aus nachhaltigen, nachwachsenden Rohstoffen, anders als herkömmliche Kunststoffverpackungen, die aus endlichem fossilem Erdöl produziert werden. Diese Methode ist nicht nur in der Herstellung nachhaltiger, sondern das Material zersetzt sich am Ende der Wertschöpfungskette deutlich schneller und gestaltet sich somit umweltfreundlicher.

Forschende der Universität Bayreuth haben ein Verfahren entwickelt, mit dem aus einer Verbindung von Orangenschalen und Kohlenstoffdioxid ein Polycarbonat entsteht, das ähnliche Eigenschaften wie herkömmliches Plastik besitzt. Dabei wird der Naturstoff Limonen aus den Schalen extrahiert, oxidiert und mit Kohlendioxid verbunden, woraus dann der biobasierte Kunststoff hergestellt wird.

Diese Alternative zu Kunststoff bietet einige Vorteile: die antimikrobiellen Polymere können die Anlagerung von E.Coli-Bakterien verhindern und sind damit für den Einsatz in medizinischen Bereichen gut geeignet, da das Infektionsrisiko sinkt. Darüber hinaus ist der Kunststoff wasserlöslich und würde damit nicht zur Verschmutzung der Meere beitragen wenn es einmal hineingelangt. Bioplastik kann übrigens nicht nur aus Orangenschalen, sondern ebenso aus vielen weiteren biologischen Roh- und Reststoffen gewonnen werden.

Designer-Lampen aus Orangenschalen

Eine weitere Möglichkeit die Orangenabfälle weiterzuverwerten ist es daraus Design-Gegenstände herzustellen. Das italienische Unternehmen

Krill Design hat aus Orangenschalen eine Lampe designt. Die Lampe entsteht in einem 3D-Drucker wobei die Orangenschalen als Druckmaterial dienen. Aus einer Mischung der Schalen und einer biopolymeren Basis entsteht ein samtiges und robustes Material, das nach dem Druck stark an die Oberfläche von Orangen erinnert. Die Lampe wird durch einen einzigen geschmolzenen Faden aus dem Biomaterial in einer fortlaufenden spiralförmigen Bewegung gedruckt. Das Verfahren nennt sich "Vase Mode" und verleiht der Lampe die charakteristische gerippte Haptik. Für eine Lampe werden die Schalen von zwei bis drei Orangen benötigt. Aufgrund ihrer Zusammensetzung ist die Lampe biologisch abbaubar, kompostierbar und recyclebar. Die Haltbarkeit wird dadurch jedoch nicht eingeschränkt.

Neben den zwei Lampen produziert Krill Design auch ein Tablett und ein Glacette (Kühlbehältnis für Getränke) aus Orangenschalen – ebenfalls über 3D-Druck. Alle werden mit der „Vase Mode“-Methode hergestellt. Alle Design-Gegenstände erinnern durch ihre Farbe und ihre Struktur an das Ausgangsmaterial, die Orangenschalen.

Das Ziel des Unternehmens ist die Wiederverwendung von organischen Abfällen aus der Lebensmittelindustrie durch einen Prozess der Kreislaufwirtschaft, bei dem natürliche Ressourcen zu Öko-Design-Produkten verarbeitet werden.

Garn und Textilien aus Orangenabfällen

Das ebenfalls in Italien ansässige Unternehmen Orange Fiber stellt aus den Fasern von Orangenschalen Textilien bzw. Garn her. Orange Fiber ist weltweit die erste Marke, die nachhaltige Stoffe aus Zitrusfruchtabfällen herstellt. Die innovative Technologie zur Herstellung der Cellulose Fasern ist seit 2014 in den wichtigsten produzierenden Ländern auf der ganzen Welt patentiert.

Die zwei Gründerinnen entwickelten ihre Methode auf Grundlage einer Forschungsarbeit, dessen Forschungsfrage war, ob ein hochqualitatives Seidentuch aus Zitrusfruchtschalen hergestellt werden kann. Für die Herstellung wird aus den Orangenabfällen Zellulose extrahiert und in eine biologisch abbaubare Faser umgewandelt. Anschließend wird diese zu Orangenfasergarn oder Fasermischungen mit Seide hergestellt. Die Zellulose wird dazu mit chemischen Reagenzien zu Garn verarbeitet, gefärbt und kann nachfolgend mit anderen Textilien wie Baumwolle oder Polyester gemischt werden.

Neben der nachhaltigen Gewinnung des Garns und der Nutzung von natürlichen Rohstoffen in der Textilindustrie, haben Textilien aus Orangenfasern den Vorteil, dass in ihnen noch immer ätherische Öle enthalten sind, die sich mit Hautkontakt und Wärme freisetzen und damit während des Tragens die Haut pflegen.

Recycling von Lithium-Batterien mithilfe der Schalen

Eine weitere Form der Wiederverwendung ist die Nutzung von Orangenabfällen beim Recycling von alten Lithium-Batterien. Da die klassischen Prozesse des Recyclings von Batterien Schadstoffe erzeugen, wurden zunächst Methoden entwickelt, die die Verwertung von Batterien mithilfe von weiteren Chemikalien ermöglichen sollen. Mittlerweile können die Chemikalien durch Orangenschalen ersetzt werden. Bei beiden Methoden werden die Edelmetalle aus den verbrauchten Batterien abgespalten und können später bei der Herstellung von neuen Batterien wiederverwendet werden.

Dazu werden die gebrauchten Batterien zunächst geschreddert und zerkleinert. Anschließend werden die Edelmetalle aus der Masse extrahiert, indem sie in einer Mischung aus Säuren und Chemikalien unter Hitze aufgelöst werden bevor die anderen Metalle zerfallen. Anstelle der Chemikalien soll nun auch eine Kombination von Orangenschalen, die im Ofen getrocknet und zu Pulver gemahlen wurden, und Zitronensäure das gleiche Ziel erreichen. Der Prozess läuft dann ressourcenschonend mit natürlichen Reststoffen ab.

Nebenströme oder Reststoffe sind in der Lebensmittelindustrie keine Seltenheit. Gerade im Hinblick auf endliche Rohstoffe wird es in Zukunft für Unternehmen immer wichtiger sich mit alternativen Verarbeitungsmethoden zu beschäftigen, um so ressourcenschonender zu arbeiten und eine nachhaltige Kreislaufwirtschaft zu schaffen. Der Gedanke der Nachhaltigkeit spielt im B2C-Bereich bereits eine entscheidende Rolle und sollte auch im B2B-Sektor mehr Aufmerksamkeit bekommen.

Let’s simplify the future of change!