Bioplastics from residues and surpluses

Here in LEROMA`s magazine, we repeatedly address food waste and its impact on the environment. We live in a throwaway society, which is not only limited to the disposal of food, but is also evident in and outside of the food industry, especially through the nearly 19 million tons of packaging waste that is generated in Germany every year. More than half of the plastic waste is being incinerated, releasing environmentally harmful emissions as well as carcinogenic dioxins. In addition, about one truckload of plastic waste per minute ends up in the ocean worldwide, resulting in the deaths of up to 135,000 marine animals and ocean-dwelling birds each year. Researchers predict that in 2050, there will be more plastic than fish floating in our oceans.

Refillable containers, deposit systems as well as recycling should at least partially counteract the problem, and to avoid additional packaging materials that are supposed to provide info about the product, some companies are now using AR technology.

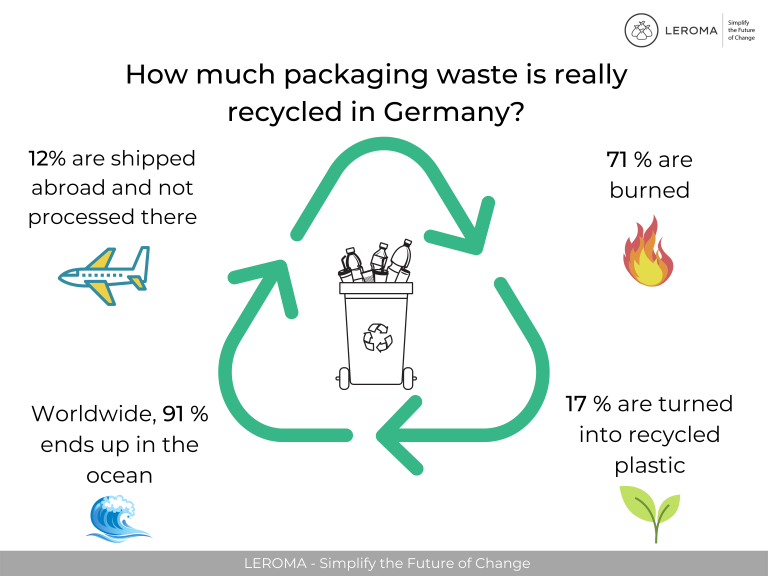

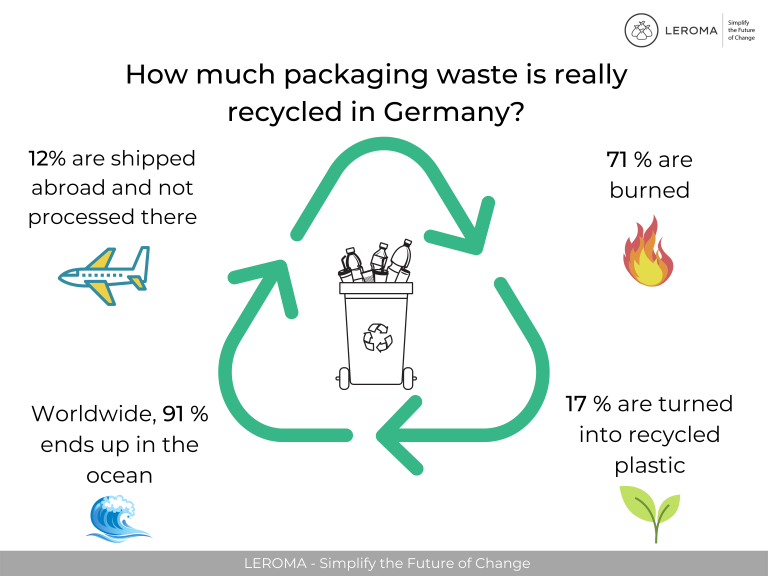

Although statistics show that up to 70% of the packaging waste generated in Germany is recycled, just 17% of it is traceably processed into recycled plastic, which is often not of the same quality as new plastic. The rest is being incinerated. Furthermore, packaging waste is counted as recycled even when it is exported to other countries for disposal. So consumers are confronted with numbers that don't convey what's really going on.

Consequently, if you look closely, Germany is not doing as well as many of us think. Nevertheless, we are still pioneers, because worldwide only 9% of plastic waste is recycled. One of the reasons for this is that other countries don't even have incineration plants, which means that plastic that is not recycled ends up in our environment and, above all, in our oceans. This corresponds to 91% of the plastic waste produced worldwide!

To solve this problem, various industries are looking for alternatives to the environmentally harmful plastic. Nowadays, paper is increasingly being used for disposable packaging. When used once, however, paper bags are less sustainable than plastic because large quantities of water are needed to produce them. The production of 1,000 plastic bags uses 220 litres of water, while paper bags use almost 3,800 litres. Therefore, paper bags would have to be used at least four times to surpass plastic bags in terms of sustainability.

Another approach is to permanently reduce the amount of packaging waste by creating substitutes that decompose faster than conventional plastics. This week we have been looking at innovative processes that offer a joint solution to two problems at once: food waste and packaging waste.

Packaging alternatives from residual materials and surpluses

Plastics as we know them are almost always based on petroleum and more than half of them are used for disposable items. They wrap countless products in our supermarkets, for example, to protect them from outside influences such as contamination, damage, water vapor or light. Because of these protective properties, plastics cannot always be avoided, but it is possible to replace them with

bioplastic.

Bioplastic refers to packaging that is made entirely or largely from renewable raw materials. (However, the terms "bioplastic" or "bioplastics" are not trademarked, meaning there are no legal requirements or conditions that must be met in order to use the terms for its products, which is why they are not used consistently).

In this article, we would like to introduce you to the different types of bioplastics that exist or are being developed on the market.

Bioplastics from starch

Starch is an organic compound, a carbohydrate, which is formed by plants. Starch-rich foods from which starch is extracted include cereals, potatoes, rice, vegetables and legumes, but corn and sugar cane have been the main crops used to produce bioplastics.

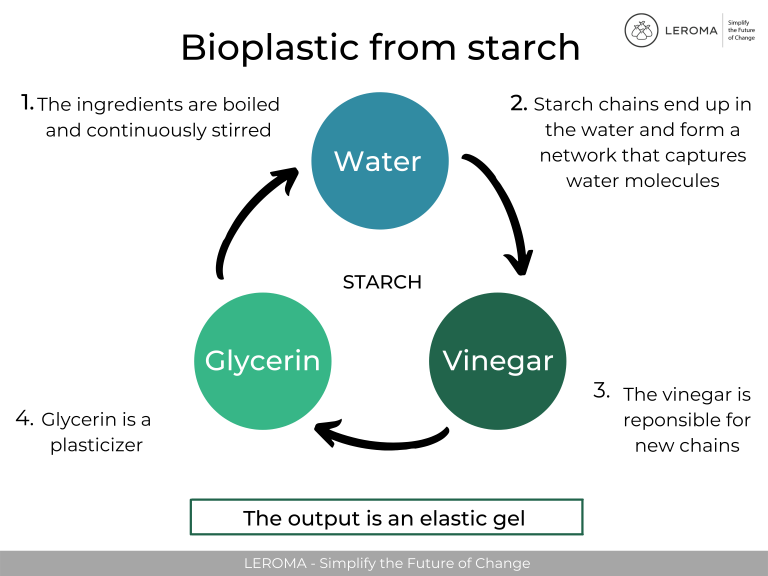

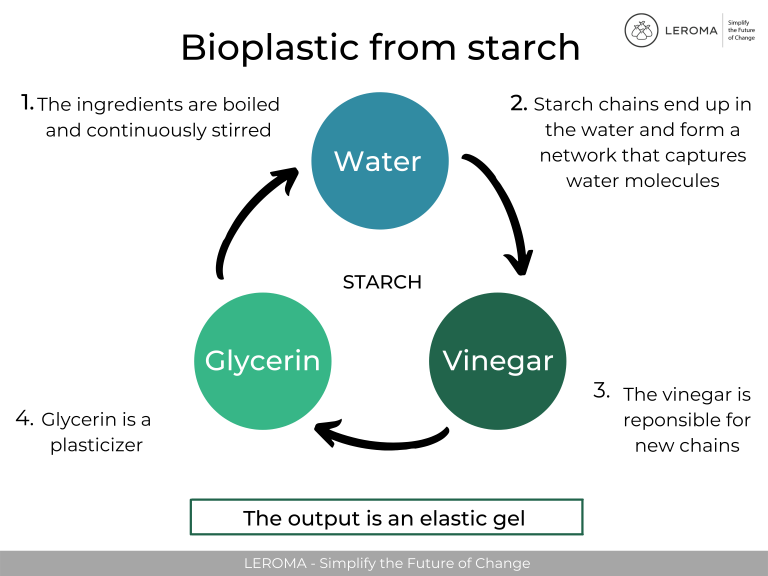

To do this, the extracted starch is mixed with an equal amount of vinegar and glycerin and four times the amount of water. The mixture is stirred continuously at temperatures between 175 and 220 °C until it becomes thick. The heated starch granules, visible only under a microscope, burst when heated and the starch chains end up in the water, forming a kind of net that traps many water molecules. The vinegar breaks up these chains so that they can arrange themselves into new, long chains, and the glycerin acts as a plasticizer, which gives elasticity and suppleness to the plastic produced. The result is an elastic gel.

It is further stirred at the same or lower temperature. The longer the mixture is heated and stirred, the more stable the bonds become. After ten minutes at the latest, the mass is viscous and translucent. After it has cooled somewhat, it can be spread on a flat surface or poured into a mold.

It is dried in the air for about a week or at 60 to 70 °C for two hours. The still soft mass can be formed into shells or tubes, for example by wrapping it around objects in the desired shape and then drying it.

Thermoplastic starch forms the highest market share of bioplastics, at around 80%. The term describes biopolymers that can be thermoplastically formed, i.e. they can be deformed within a certain temperature range. The process is reversible, as the starch mixture can be heated and returned to a viscous state to be reshaped as often as desired. Because of its thermoplastic properties, the starch can be processed using methods commonly used in the plastics industry. These include blown film extrusion, in which the "melt" emerges from a ring die in the form of a closed film tube, or injection molding, in which the melt is injected under pressure into a mold.

As mentioned at the beginning, starch-rich foods such as corn and sugarcane are used to produce bioplastics, but we at LEROMA are particularly interested in the approach of passing on agricultural waste and residual materials to the plastics industry for this purpose, because starch can also be obtained from

potato peels, for example. This approach is enormously important because currently raw materials are grown specifically for the production of bioplastics, although there are more than enough residual materials available that could be saved from the trash by the process. However, thermoplastic starch absorbs moisture, which is why it is often mixed with water-repellent and biodegradable polymers.

Biopolymers

Polylactic acid, a polymer that belongs to the polyesters, can be obtained from starch by fermentation. There is also a biopolymer on the market, among others, which consists of the milk protein casein and is produced from raw milk, which is no longer suitable for consumption.

PHA

Polyhydroxyalkanoates, abbreviated PHA, are naturally occurring biopolymers that are intended to replace conventional plastics, especially in the field of packaging and coatings. Years ago, a process was developed to produce PHA using food waste. The waste is converted into fat-rich acids by processes that vary from company to company. One option is to break down the food waste in a modified anaerobic digester, producing liquid fatty acids as an intermediate product. Another company breaks down the waste into short-chain fatty acids through a bacterial culture. The fatty acids are then fed to special bacteria that produce PHA in their cells. The PHA is extracted from the cells and processed into plastic.

The whole process takes seven days or less and is carbon-negative, meaning it removes more carbon from the atmosphere than it produces. It is even possible to reintroduce the plastic into this process after use. In addition to food waste itself, the methane produced during its storage in landfills or other industrial processes can also be converted into PHA.

PHA is characterized by its low water permeability and high temperature resistance, and can even be used as a filament in 3D printing. The extraction of PHA is still more cost-intensive than the production of conventional plastics, but companies should be aware that the ecological costs of conventional plastics are significantly higher.

HMF

HMF (hydroxymethylfurfural) is formed during the thermal decomposition of sugar or cellulose and partially oxidizes to DFF, a chemical compound that can be processed into bioplastics. Residual materials can also be used for this process, such as apple peels, which contain cellulose. Until now, the process was not economically viable because complex technology as well as high temperatures were required. The solution to this problem is very long, thin and reusable nanorods made of manganese dioxide, which serve as a catalyst and accelerate the partial oxidation. In addition, the structure of the nanorods increases light absorption, which is why the HMF can be converted into DFF by a photocatalytic reaction. A UV LED lamp is sufficient for this purpose. In addition, the manganese dioxide has a large contact area with the parent molecule, and tests have shown that the increased activity converts nearly 100% of the HMF into DFF. The plastic can be produced with oxygen from air at room temperature and under normal pressure conditions thanks to the new technology.

In addition to the use of biopolymers and starch, there are also attempts to produce sustainable packaging from plant residues such as sugarcane leaves or algae fibers. There are also experiments with coatings made from algae and tomato peels, which are intended to replace aluminum that is vapor-deposited onto various substrates to protect food from moisture. Chitosan, which is extracted from the shells of crustaceans, is also soon to be used in the packaging industry, for example in the production of biodegradable plastic bags.

Bioplastic from fish waste

A startup from England, looking for a use for food waste, has created a formula for a biodegradable plastic made from fish scraps. The plastic is made from fish skins and scales, which are characterized by their flexibility and strength.

The finished bioplastic is a transparent film that is especially suitable for disposable packaging because it can completely degrade in a soil environment within 4 to 6 weeks. It can even be consumed by wildlife without harming them. In addition, the film is stronger than films made with LDPE, a component of conventional plastics.

In general, bioplastics have enormous potential because biopolymers also take only six weeks to two years to completely decompose. By comparison, a plastic bag takes 20 years and a plastic bottle can take up to 450 years to decompose!

So in the long run, bioplastics help reduce litter, but this fact should not lead to a careless approach to packaging waste, as biobased plastics still take a long time to completely degrade under uncontrolled conditions.

This week, we've been looking at innovative processes which impressively demonstrate that reducing food waste and producing sustainable bioplastics can go hand in hand. Although some processes are still in development, we expect them to make it to market in the future.

Companies should start looking at alternative packaging now, as it is expected that additional taxes will be placed on plastic in the future as part of the climate change package. Of course, the changeover will not happen from one day to the next, but those who initiate the change today can save money, time and capacity in the future.

When innovative, biodegradable plastics from food waste are integrated into our everyday lives, they can create their own circular economy and have a positive impact on our environment.

Let’s simplify the future of change!