The advantage of freeze-drying over other methods

Last week we announced that in this article we would look at the process of freeze-drying, an innovative dehydration process that differs from other drying processes because it does not alter the appearance and texture of the treated products and preserves the nutrients contained in food.

The process is also called lyophilization or sublimation drying and refers to the gentle drying of products, through the removal of water. The process is used in various industries and is used in the food industry primarily for the preservation of perishable foods, such as fruits and vegetables. In the following, we would like to present the process to you step by step in detail:

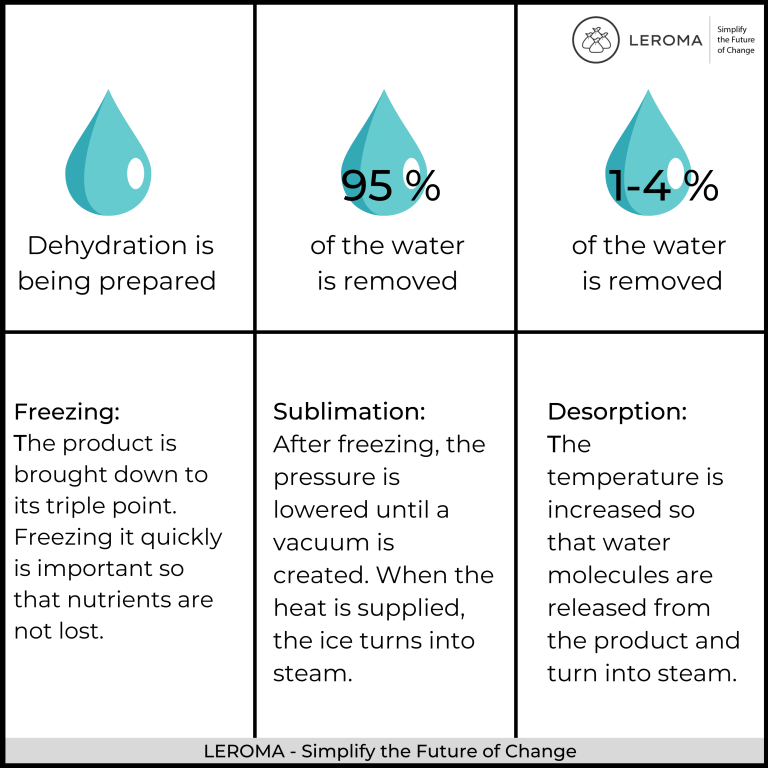

Freezing

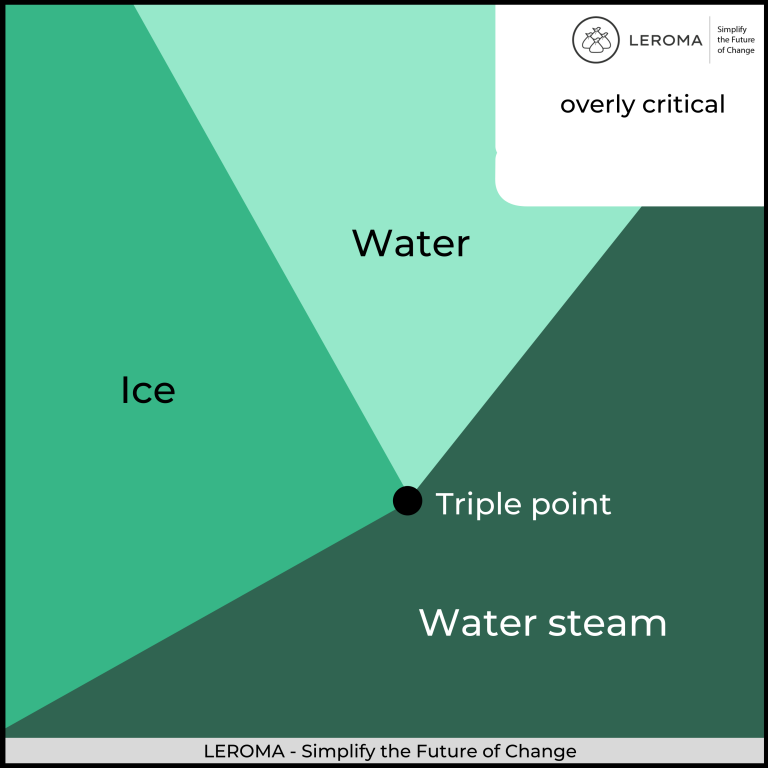

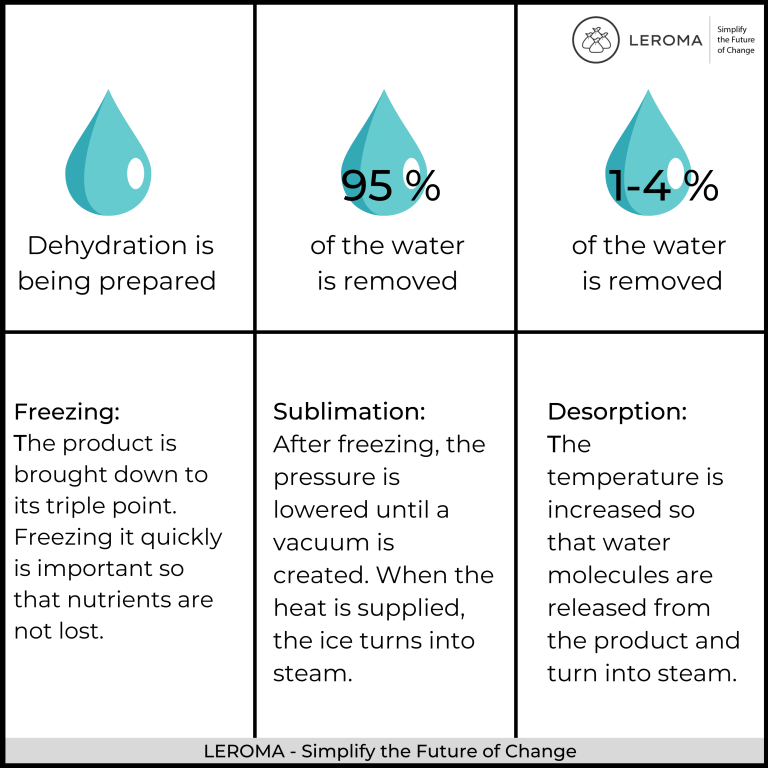

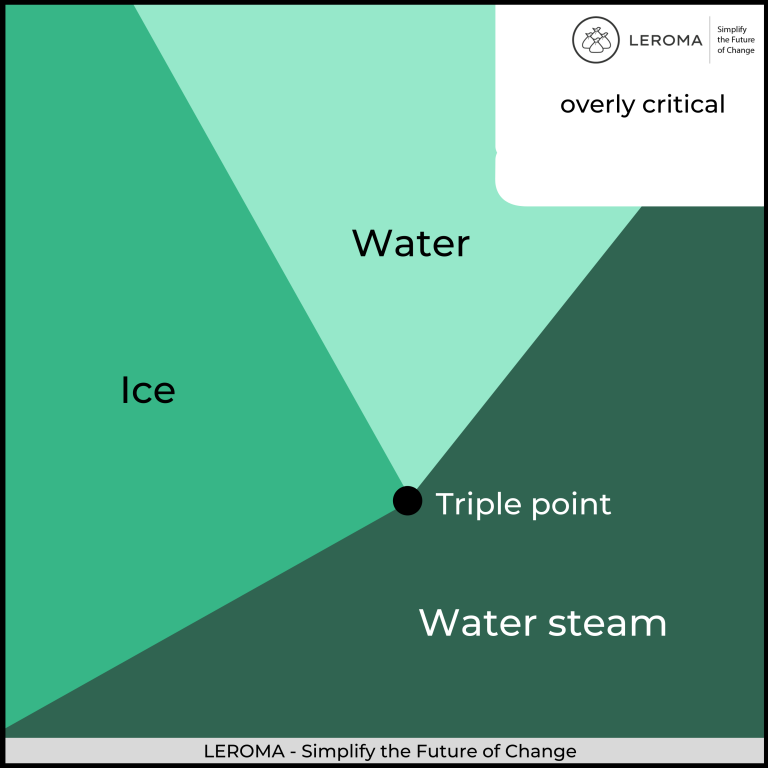

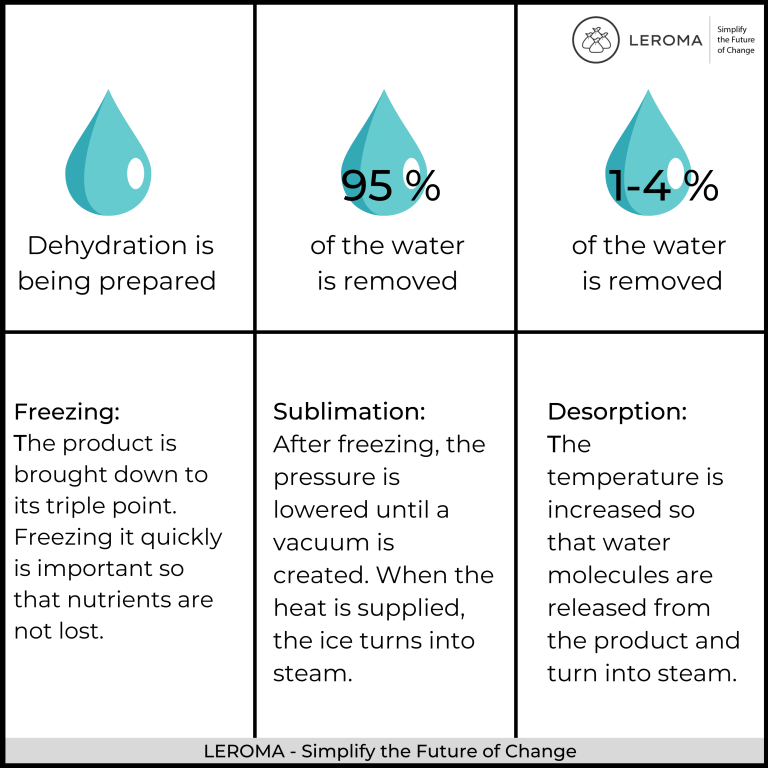

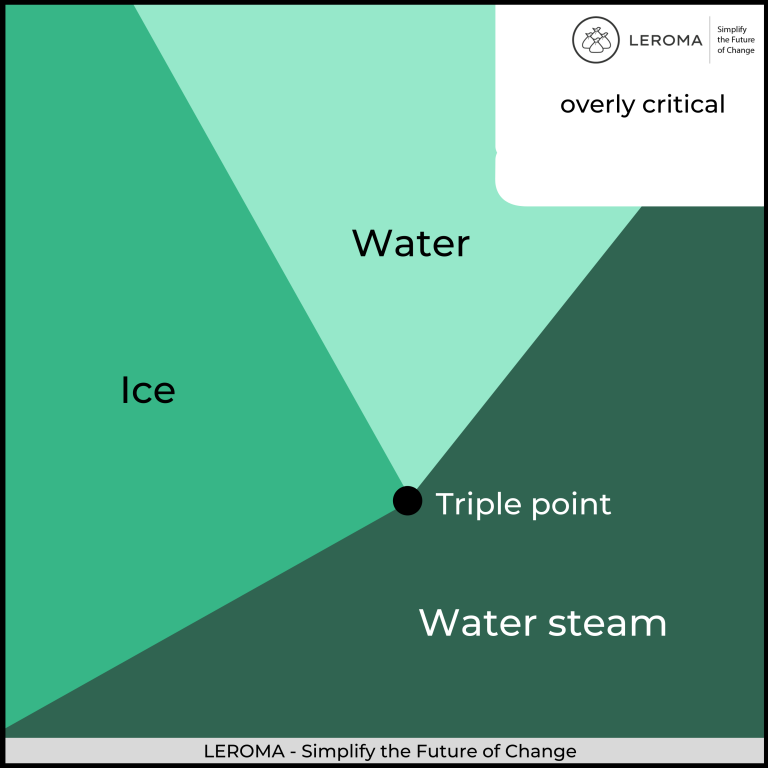

The product to be treated is frozen in a freezer, refrigerated bath or freeze dryer. In this regard, fruits and vegetables are called Individually Quick Frozen- Products, or IQF- Products, which also include fish and seafood. These products are placed directly in the trays of a freeze-dryer, whereas ready-to-eat meals are placed in special plastic trays beforehand. The product is cooled down to its triple point. The triple point is the lowest temperature of a product at which water vapor, liquid water and ice can occur simultaneously. For food products, freezing temperatures are often between -40°C and -80°C.

Generally, products are frozen slowly in the freeze dryer to create large ice crystals that evaporate more quickly later. However, in the case of food or other biological materials, ice crystals that are too large can break through the cell walls, destroying the texture and causing nutrients to be lost. So, to avoid the formation of large ice crystals, food is frozen quickly rather than slowly. This first step of freeze-drying is the most important phase, as it influences product stability and quality to a great extent.

Sublimation (primary drying)

The products are frozen under atmospheric pressure. Once frozen, the pressure is lowered until a vacuum is created. It is important that the product is completely frozen before the vacuum is created, otherwise it may expand. At this point, heat is added so that the ice sublimates, i.e., it is converted to steam and thus removed from the food.

Sublimation refers to the transition of solids to a gaseous state without liquefaction in between. It is accelerated by the vacuum. Moreover, the process is favored by the previous cooling below the triple point, which ensures that the ice sublimates and does not melt. The heat supplied is kept low so that the appearance and texture are not altered. The critical temperature that must not be exceeded varies according to the product and depends, among other things, on the pressure on the ice surface and the rate of transfer of heat into the product. Because of the low temperatures, however, sublimation can take several days, which is why a lot of energy is needed. In addition to the high energy costs, the equipment is significantly more expensive than the equipment used in other processes. Freeze-drying is therefore particularly suitable for products that can be optimized by the process or are sensitive to heat. These include fruits and vegetables, because the process extends their shelf life and thanks to the continuous low temperatures, the valuable vitamins are preserved. This is a clear advantage of freeze-drying over other drying processes that remove the water from the fruits and vegetables through high temperatures.

Sublimation removes about 95% of the water contained in the product.

Desorption (secondary drying)

After the ice has been sublimed, ionically bound water molecules still remain, bound to the product and not frozen. Since most of the contained liquid has been frozen and removed in the previous steps, in secondary drying the temperature can be increased and even be above 0°C without damaging the product. The temperature is increased to break the bonds between the product surface and the water molecules. The molecules can then be desorbed, i.e. they are converted into gas and thus removed. This phase also usually takes place under a partial vacuum, but there are products that can be processed better at higher pressure.

Once desorption is complete, the freeze-drying process is finished and the vacuum is broken, for example with nitrogen. The final product contains only an extremely low residual moisture of about 1 to 4% and is often referred to as lyophilizate. The term refers to products that are dissolved in water before use and often refers to pharmaceutical products.

In general, freeze-dried fruits have a higher quality than products dried by conventional methods. They are closest to the original form, because almost all nutrients and vitamins, as well as the taste, intense color and their characteristic texture are preserved. Moreover, they do not shrink into themselves or become more solid as is known from conventional dried fruits. In addition, freeze-dried products are porous, which means they are permeable and can be rehydrated before use, i.e. water is added to them so they take on their original shape and appearance.

Properly packaged, sealed in oxygen- and moisture-impermeable packaging, and under ideal storage conditions, freeze-dried fruits and vegetables will last longer than 12 months. This is due to the fact that the structural changes of proteins and browning are minimized by the rapid transfer of water through sublimation.

Application diversity

Freeze-dried fruits and vegetables can be sold whole, cut, or ground into powder and used as an ingredient in, for example, mueslis, smoothies, and other snacks. Food manufacturers can thus meet the growing consumer demand for real, high-quality food sources and understandable ingredient lists without artificial additives.

Most importantly, freeze-drying allows the valuable ingredients of fruits and vegetables to be preserved and used at a later date. This means that the healthy raw materials are available all year round and food produced with them is not subject to seasonal fluctuations.

Other foods, such as insects, which are now available in Germany both whole and as a component of protein bars, can also be freeze-dried. As mentioned at the beginning, freeze-drying can be used in various industries. In the pharmaceutical industry, for example, there are countless bacteria, sera, antibiotics and vaccines, as well as cells and tissues that can be permanently preserved by the gentle removal of water and rehydrated with water before use.

The innovative process is costly, but it ensures high product quality and outperforms many alternative methods because of the gentle process.

Let’s simplify the future of change!