Ways to reduce the waste of fruits and vegetables

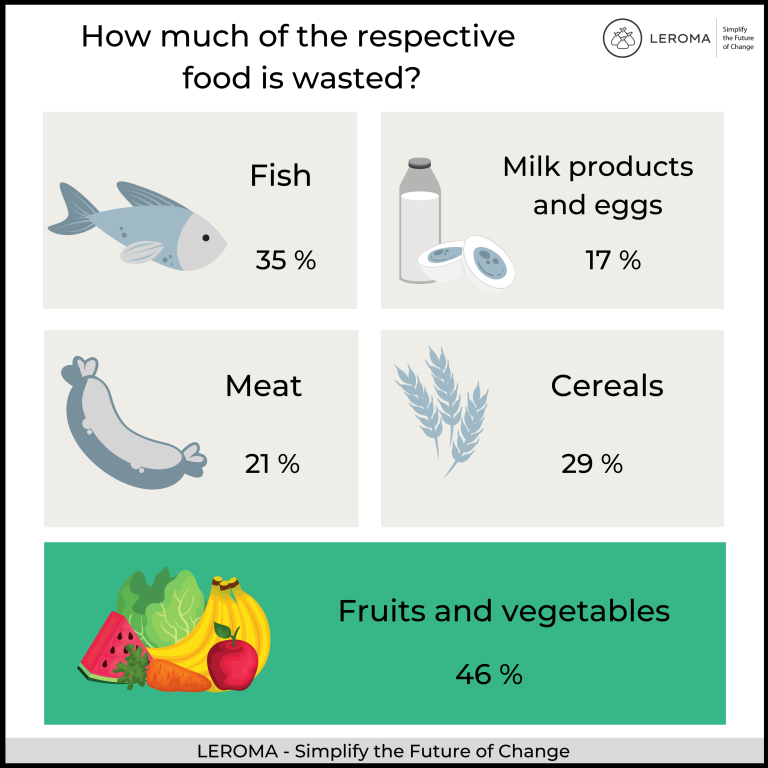

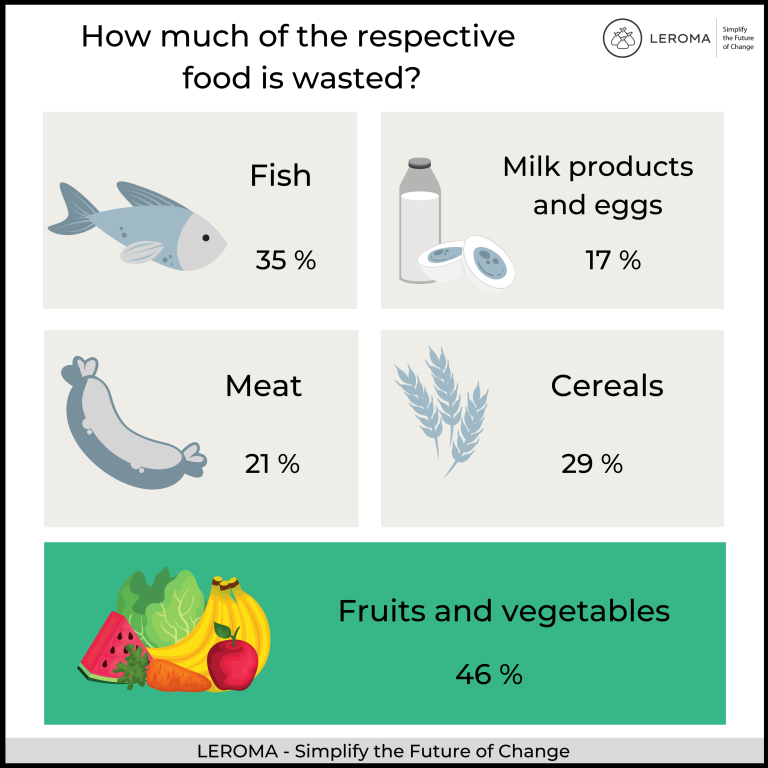

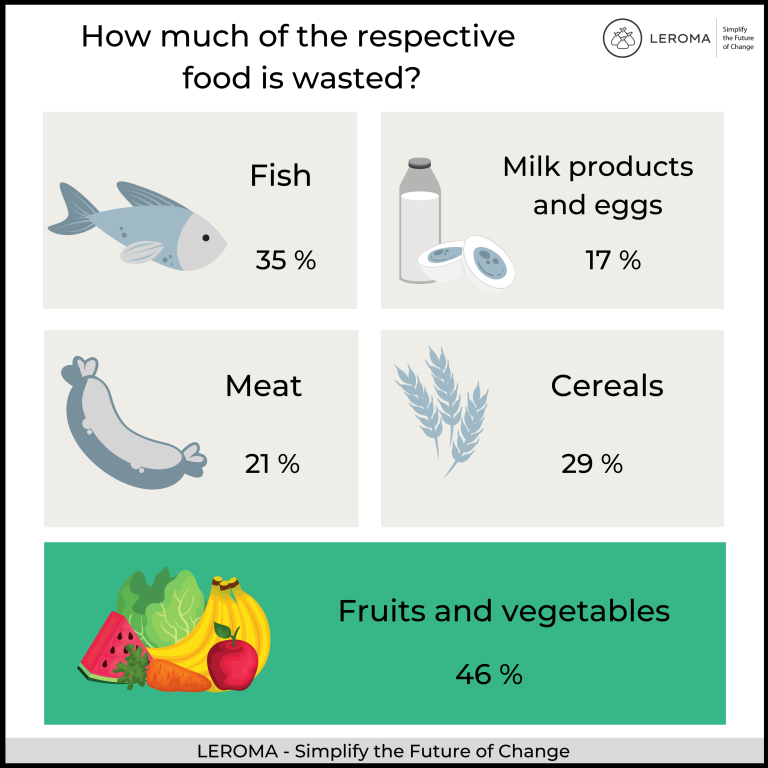

Food waste is a pervasive and urgent global problem that can be captured in various figures: In Germany, about 20 million tons of food are discarded annually, worldwide, one third of all food produced is wasted, and over 800 million people suffer from hunger. Both within Germany and worldwide, almost half of the waste consists of fruit and vegetables.

On the one hand, this can be attributed to consumers, who dispose of 75 kilograms of food per capita annually, mainly fresh and perishable items such as bread and fruits/vegetables.

One reason for this could be the constant availability at low prices, which often tempts people to buy more than they need. In addition, there is an oversupply, because the large selection offered to consumers around the clock means that supermarket shelves are often still half full at the end of the day.

Whether this is really necessary is debatable, as many consumers feel overwhelmed by the choice. Either way, they are not the only ones responsible, because a look at the beginning of the value chain shows, that massive sorting is already taking place in the fields. 50 million tons: That's the staggering amount of fruit and vegetables that never make it to our supermarkets because they're not the right shape or size, or because they have minimal visual defects.

However, the biggest cause of fruit and vegetable disposal, both in private households and in industry, is rapid deterioration.

The deterioration of fruits and vegetables at the beginning of the value chain

Spoilage of fruits and vegetables in some cases begins before harvesting with the so-called storage diseases, which only become visible after the produce has already been harvested and stored. They are usually caused by fungi, bacteria or nematodes. It is possible to start at this point, for example with the application of succinate dehydrogenase inhibitors, or SDHI for short. Inhibitors block the action of enzymes, such as in this case succinate dehydrogenase, a protein that is produced by all living organisms and plays a role in cellular respiration. The term "cellular respiration" describes the consumption of oxygen, for example in humans, to break down nutrients such as fatty acids for energy production. This process is vital for cells. SDHI therefore ensures that this process is stopped in molds and bacteria, leading to the death of the pests. The inhibitors are not effective against all pests and, most importantly, have no negative effects on humans. Agents that can be used as inhibitors against succinate dehydrogenase include bixafen, boscalid, fluopyram, fluxapyroxad, penthiopyrad, isopyrazam, or sedaxane. SDHI is sprayed on food before harvest to reduce the development of storage diseases, ensuring greater stability during storage.

Stakeholders along the value chain need to regularly inspect fruits/vegetables, whether during storage, transportation, or at retail, to weed out products that are affected by diseases that can be transmitted to the other fruits. This includes, for example, botrytis rot, which forms brownish, sunken rot spots and can quickly spread to the rest of the products. In addition, the characteristics of each raw material must be taken into account, as incorrect storage accelerates deterioration. For example, potatoes should be stored in a cool, dark place because they produce solanine when exposed to light; strawberries must be refrigerated, and the greens of carrots or radishes should be removed because they extract water from the raw materials. These facts are common knowledge, but remain of great importance.

Especially in retail, these conditions are often no longer respected; potatoes lie open in the light and strawberries rarely in the refrigerator compartment, because it is assumed that the products will sell the same day. If this is not the case, they often have to be sorted out directly. In addition, fruits/vegetables are specially ripened with the gas ethylene, which is secreted by apples, for example, so that yellow bananas and red apples can be offered in the supermarket, which are more attractive to the consumer than unripe products. However, this causes decay to begin earlier.

The industry is gradually realizing, however, that consumers are becoming more environmentally aware and quite a few would be willing to buy "ugly" or unripe fruits and vegetables as long as they are of good quality. In Germany, there is already a startup that sells not only products with expired best-before dates that are still edible, but also fruits/vegetables that do not make it into stores because they are "ugly." This model is one that not only retailers could follow in the future. Wholesalers and food producers could also expand their product portfolio to include fruits and vegetables with visual defects in order to reach new customers and counteract the waste of raw materials.

Methods for preservation of fruits and vegetables

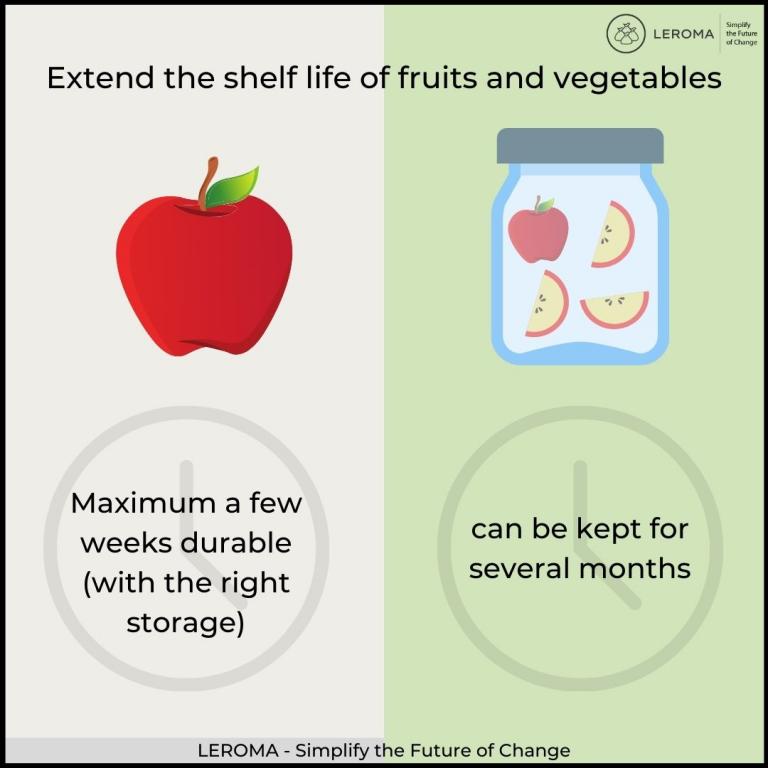

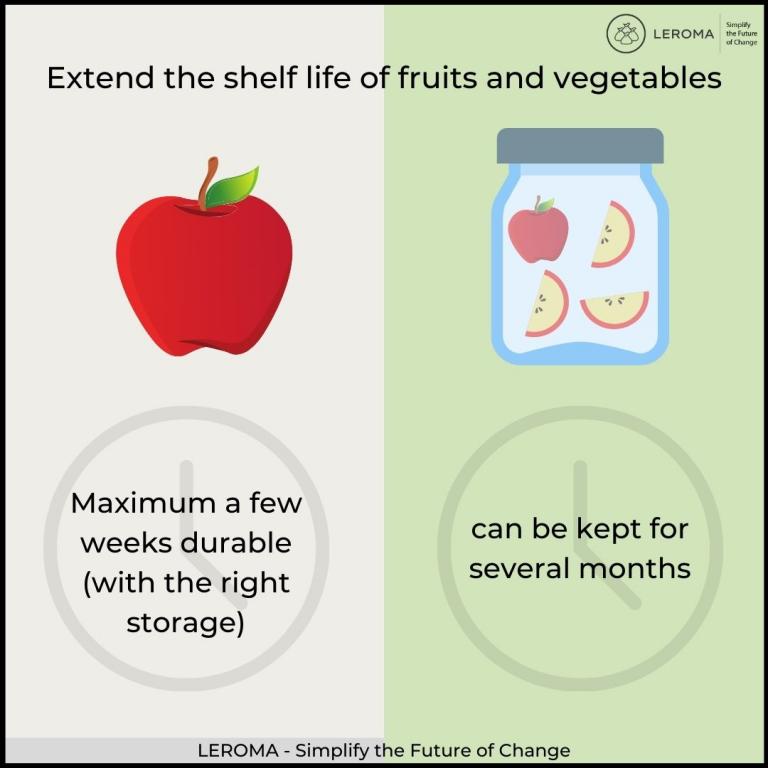

Often more fruit and vegetables are harvested than can be sold in the next few days. If it is already foreseeable that there will be surpluses, these can be preserved by pickling, for example. Pickled fruits and vegetables can be stored for several months. However, after bottling, the pickled product is briefly heated to a high temperature to kill bacteria, which preserves proteins, carbohydrates and minerals but loses many vitamins.

Alternatively, fruits and vegetables can be dried. Dried fruits have as many vitamins as fresh crops and can even stimulate digestion. Here, however, it depends on the drying process, because even in this production process at high temperatures many vitamins can be lost. So it is important to dry slowly and gently. If stored correctly, dried fruit can be kept for six to 12 months.

Another processing option is fermentation. This makes raw materials more digestible and gives them a longer shelf life. In addition, they acquire an intense flavor, which, however, is not to everyone's liking. In Germany, Sauerkraut is a well-known example of fermentation, but the process can be applied to countless vegetables and fruits. The process is made possible by lactic acid bacteria that occur naturally on fresh fruits and vegetables. The raw material to be fermented is chopped up, mixed with salt and crushed so that the cell juice comes out.

The salt promotes the escape of water. The process continues until the raw material is completely covered by liquid, called brine. At this point, fermentation begins, i.e. the lactic acid bacteria convert the sugar or starch contained in the raw material into lactic acid, in which only the bacteria and no harmful microorganisms can survive. The process is characterized by the fact that high temperatures are not necessary for production, which means that nutrients are better preserved.

Fermented foods can often be kept for months, sometimes even years, and do not lose any of their valuable ingredients over time. In addition, they have a positive effect on our digestion.

Fruits and vegetables can also be frozen. Here, too, vitamins are lost because some raw materials are blanched, which means they are cooked briefly in scalding hot water and then quenched in ice water before being frozen to kill germs and thus extend their shelf life. But overall, blanching slows spoilage so that more of the nutrients it contains are preserved in the long run. The fruit/vegetables are then flash frozen, as this is the way to preserve most of the ingredients.

The examples given show various methods of preserving fruits and vegetables for later use. However, there have been hardly any approaches to date to preserve fresh fruit in its natural state for longer, so that it remains edible for longer. Particularly in light of the need to avoid plastic packaging, which protects against moisture, for example, the food industry faces a major challenge.

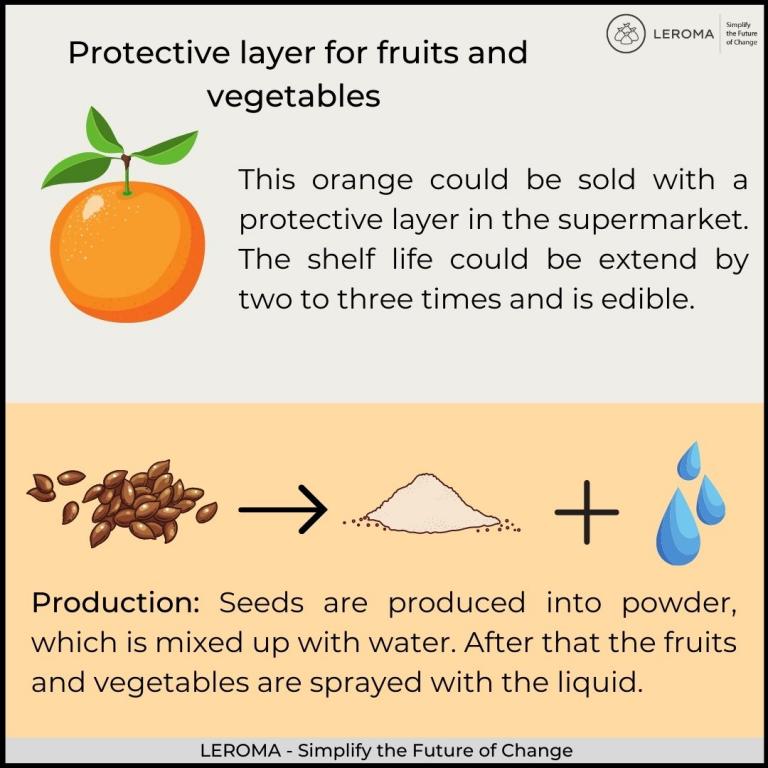

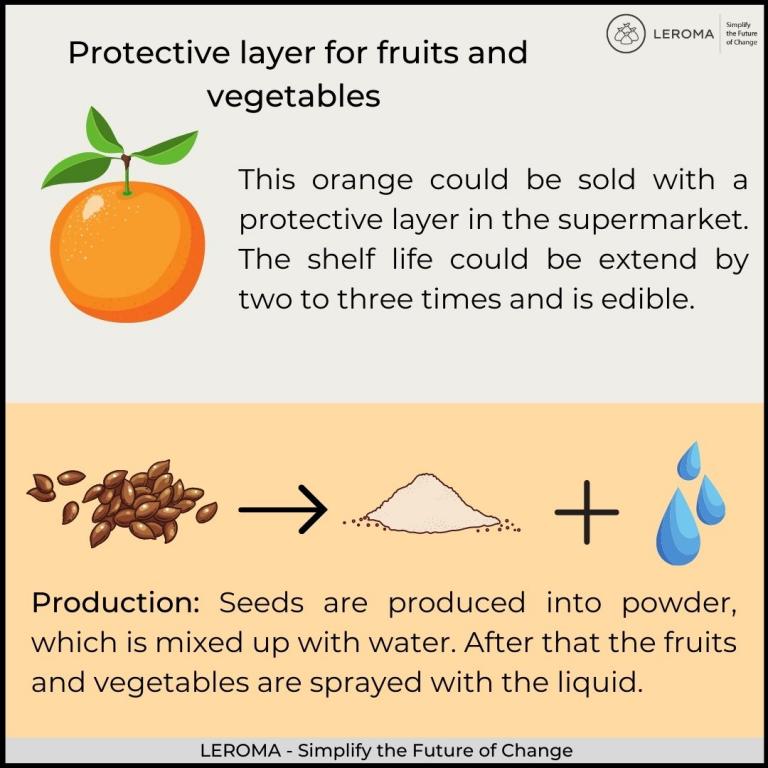

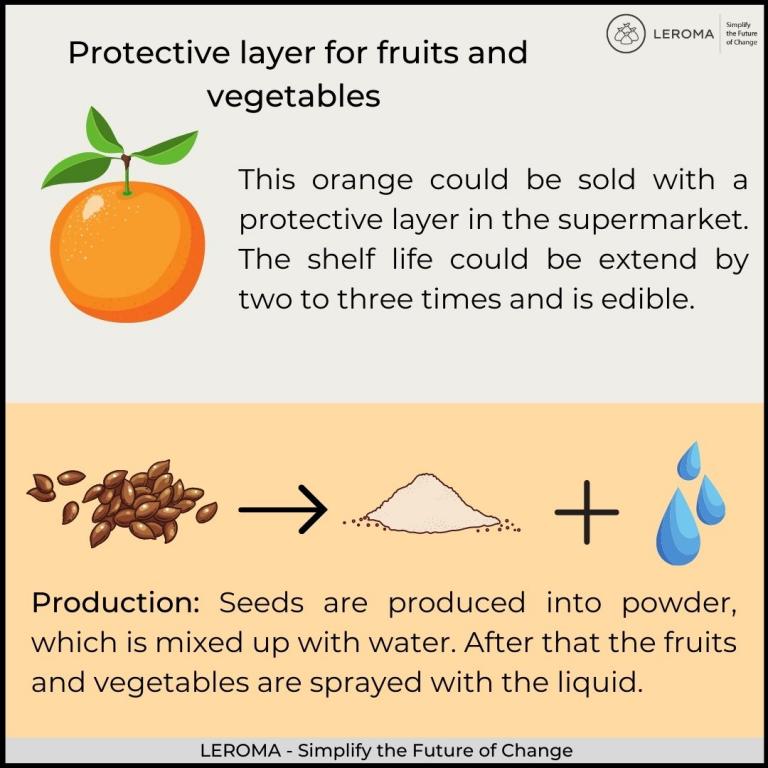

Since 2019, the startup Apeel, founded in 2012, has been attracting attention in this regard with an innovation that significantly slows down the deterioration of fresh fruits and vegetables without changing their condition. The innovation consists of an edible protective layer that protects against moisture and oxygen, the two biggest causes of decay, making it an effective replacement for plastic packaging.

Coating fruit and vegetables

The coating of fruits and vegetables has long been known in the industry; for example, many citrus fruits are coated with a wax layer that prevents the fruit from drying out. However, such coatings are not suitable for consumption and are only applied to peels that are not consumed. Therefore, Apeel's natural protective coating is a much needed alternative. It consists of lipids, vegetable fats found in the peels, seeds and pulp of fruits and vegetables.

The company primarily uses by-products such as the seeds and peel components that would normally have no other use to create a powder that is mixed with water for application. Fresh fruits and vegetables are dipped into the liquid or sprayed with it. The liquid dries and forms an air-permeable film that is edible because it is made of vegetable matter that is already naturally present in the food. In addition, the coating does not affect enjoyment because it is invisible, odorless and tasteless. Above all, it extends the shelf life of the raw materials by a factor of two to three.

Moreover, the natural protective coating is inexpensive. The low price per fruit is of no consequence in the retail trade, because there are fewer costs associated with the disposal of food waste. Therefore, the product can be offered to the consumer at an unchanged price. The innovation is already being tested in Germany by the Edeka supermarket chain, although so far only for fruits and vegetables whose peel is not eaten, such as avocados, oranges and tangerines. Rewe also offers products with a coating, but from a different manufacturer.

The liquid used there is also applied by dipping the fruit or spraying and consists of a mixture of sugar, cellulose and vegetable oils. The thin skin is primarily intended to prevent oxygen from penetrating the sensitive interior of the raw product, thus doubling its shelf life. In addition, this coating is also tasteless and well tolerated.

Fruit and vegetables that not only do not require plastic packaging, but also remain freshly harvested for twice as long as usual, are no longer dreams of the future, as we can see. However, wrapping with a natural protective layer is not the only process we can already use to reduce the waste of perishable foods.

High Pressure Processing

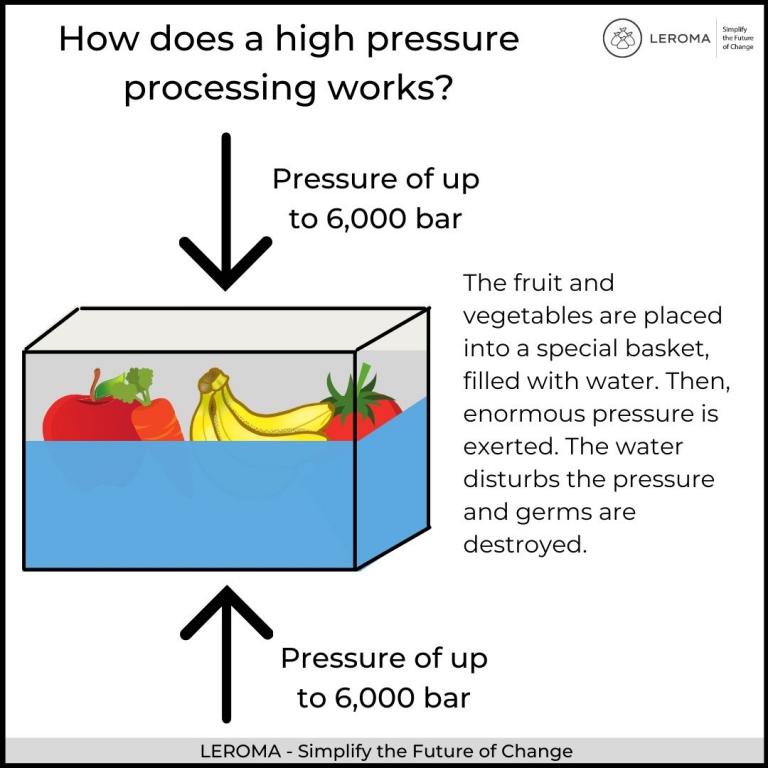

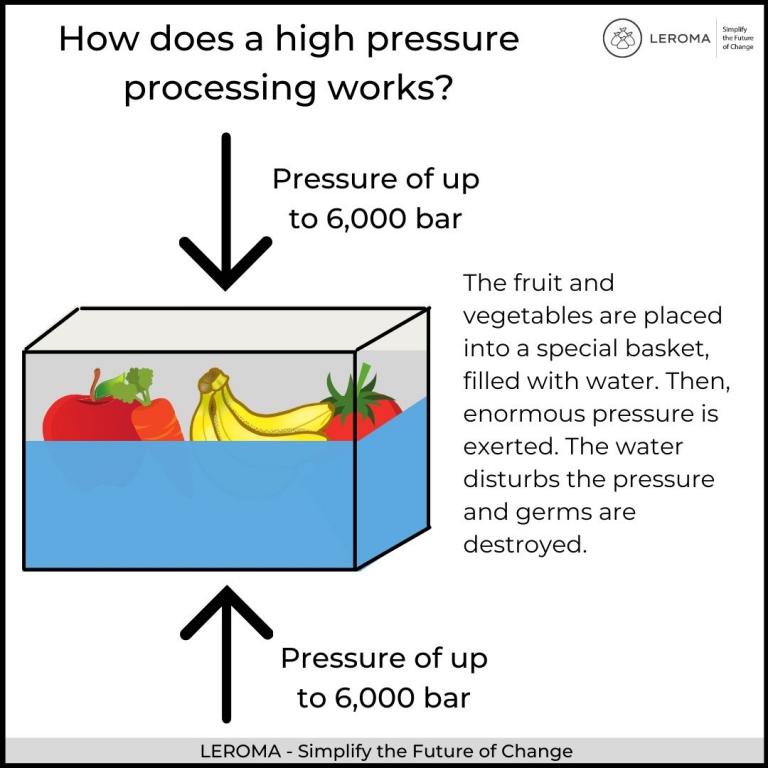

In addition to the preservation methods we have presented in this article, there are also technical processes that can be used to extend the shelf life of foods such as fruits and vegetables. One example is high-pressure processing, which we would like to introduce to you below.

Uhde High Pressure Technologies GmbH (Uhde 350-60 Anlage, HPP Center Quakenbrück, Germany)

High pressure pasteurization (also High Pressure Processing or HPP), is a non-thermal process for the gentle preservation of food products, which does not require any chemical additives at all.

Products are placed in special perforated baskets with flexible and watertight packaging and conveyed into the high-pressure vessel. Then the process water is filled into the vessel and electric high-pressure pumps increase the pressure up to 6000 bar. The hydrostatic pressure acts immediately and evenly on the entire product. It prevents product damage and ensures sophisticated inactivation of harmful microorganisms and enzymes in just a few minutes. In the end, it results in increased safety and up to ten times longer food shelf life. Since no heat is introduced, the nutrients, bioactive ingredients and flavor of the food are preserved.

When treating fruits and vegetables with the HHP process, not only are pathogens and bacteria rendered harmless, but enzymes are also deactivated. This prevents the fruit from turning brown and preserves its texture and appearance. The gentle process has proven particularly successful for vegetable / fruit and meat products.

Next week we will introduce you to the

process of freeze-drying, which is used in various industries to preserve products and has several advantages over traditional drying methods.

Let’s simplify the future of change!