Why Walnuts Are A Sustainable Resource

Two weeks ago, we emphasized in LEROMA's magazine that we want to reduce food waste and contribute to a sustainable circular economy with our surplus exchange. It is necessary to draw attention to the issue of waste over and over in order to start changing it. We at LEROMA focus especially on the beginning of the value chain, where valuable raw materials are thrown away because they have no apparent use.

In our first article on the topic of the circular economy, we told you about the potential usage of

coffee residues in the food industry and other sectors. These include the protective layers of coffee beans, which are often removed during harvesting, and byproducts such as coffee grounds. Today, once again, we want to raise awareness of the potential of raw materials that are still thrown away in large quantities by focusing on a new topic. In the following text we will deal with walnuts.

The walnut

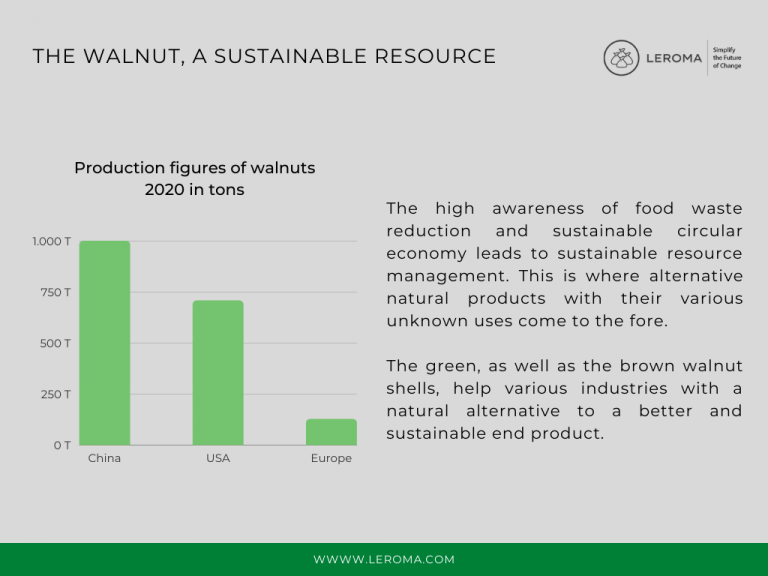

Walnut trees are grown all over the world for their fruits, which have been used as food since the Stone Age and contain many valuable ingredients, such as unsaturated fatty acids, proteins, vitamins and minerals. The most common is the "true walnut" (Juglans regia). The main producer is China, where more than one million tons of walnuts were harvested last year, and the second place is occupied by the USA, with a harvest of 707,600 tons. For comparison, in the whole of Europe "only" 127,000 tons of walnuts were harvested in the same period.

During harvesting, the nuts are freed from the green fruit shells, which in most cases are disposed of directly, although they have so much to offer.

The use of walnut shells (green fruit shell)

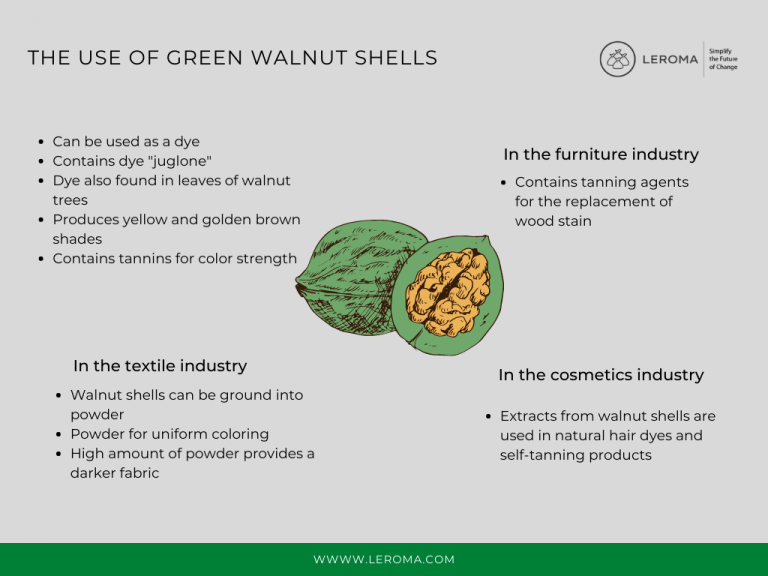

The green walnut shell is mainly used as a

dye because of the dye "juglone" it contains. Juglone is formed on the one hand by the ingredient hydrojuglone, which already oxidizes to juglone in air, and on the other hand by pyrogallol, which is added to an alkaline solution to oxidize. Ideally, shells that have already turned brown are used, because more hydrojuglone has oxidized to juglone there than in the fresh, still green shells. The fresh shells can be soaked in water to produce even more juglone, but the soaking time should be at least 24 hours. Incidentally, the dye is found not only in the walnut shells, but also in the leaves of the walnut tree. Again, the brown discolored leaves contain more juglone than fresh ones. The juglone from walnut leaves produces yellow and golden brown hues, while the shells produce warm browns. In addition to the dye, the shells also contain a large amount of tannins, which enhance the dyeing power. We notice this by the fact that our fingers already turn dark when we just touch the green peel with our bare hands.

The green walnut shells can be dried and optionally ground into powder to make them durable for storage and use throughout the year as a dye, especially for textiles. For this purpose, the textiles do not even need to be boiled, it is enough to let them steep in cold water or at temperatures just up to 40 °C with the dried shells or the powder for 8-12 hours. The powder produces a more uniform coloration than the unground shells. The more powder is used, the darker the fabric becomes. If the weight of the added powder is equal to the fabric weight, very dark browns are produced. For light dyeings, 10-40% of the fabric weight is enough.

Dyes from the green walnut shells can replace wood stains thanks to the tannins they contain. In addition, the dyeing power of the shells is also used in the cosmetics industry. Extracts from walnut shells are found in natural hair dyes and self-tanning products. In addition to the dye juglone and tannins, green walnut shells also contain bitter compounds that can be added in the production of liqueurs. However, the green fruit shell is not the only "waste product" of the walnut. The hard, brown nut shell, which contains the edible kernel, is also suitable for various applications, which we present in the following:

The use of brown walnut shells

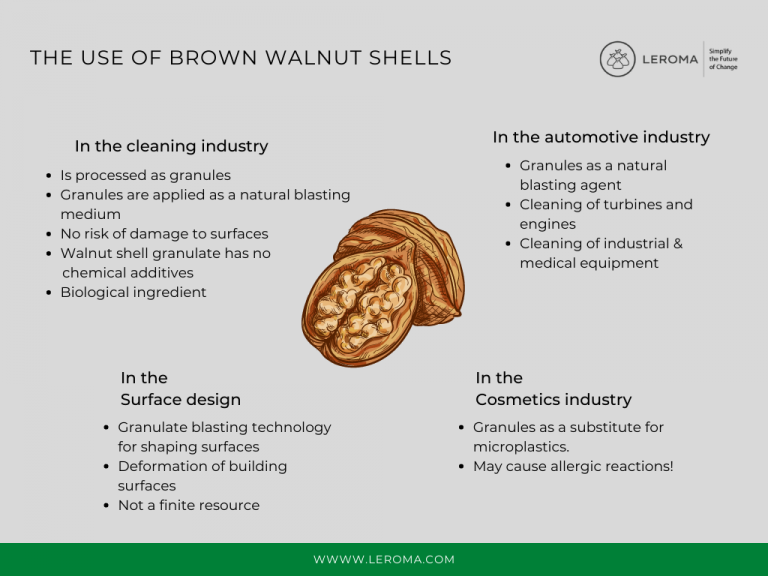

Due to its hardness, the brown walnut shell is often processed into

granules , which are used in the cleaning industry, for example. There, the granules act as a

natural blasting agent that can be used to clean and polish metal surfaces and remove chemical coatings, among other things. Conventional blasting media such as steel shot, silicon carbide or aluminum oxide are very hard and carry the risk of damaging the surface that is to be cleaned. Walnut shell granules, which are completely free of chemical additives, are softer and therefore remove only the contaminants without scratching the underlying substrate surface.

Using the air-blast process, where the abrasive impacts the surfaces at high velocity, the granules can clean and maintain turbines and engines or industrial and medical equipment instead of conventional abrasives. In addition, any residues, for example in engines, are harmless because they burn off even at lower temperatures.

This blasting technique is not only used for cleaning, but also for surface design, i.e. the surface is roughened, matted, hardened or structured. In addition, building surfaces can be given a specific shape by grinding them with the friction body. So far, mainly sand has been used as a friction body in classic sandblasting, but it is a finite resource. For this reason, walnut shells are an ideal alternative here as well, since they are available in inexhaustible quantities and usually at lower prices.

The walnut shell granules are also very suitable as a biological ingredient for hygiene products, especially surface cleaners, or as a filler for other cleaning products, where it increases the volume without changing the essential properties of the products.

In the cosmetics industry, the granules can replace microplastics. However, in both the cosmetics and cleaning industries, it is important to note that products containing walnut shells can cause allergic reactions.

Further application of the brown walnut shells result from the irregular shape. The shell is composed of irregular and interlocking cells, each of which is interlocked with at least 14 neighboring cells. This complex structure results in high tensile strength, as the cells must be cut through rather than simply broken apart. Therefore, walnut shells can be used, for example, to increase the density and strength of particleboard and other building materials, or to make their own resistant material.

When walnut shell powder is added in the manufacture of ceramics, it increases the porosity of finished products.

Walnut shells can also serve as a kindling for stoves, for example. They generate a lot of heat and should therefore only be used in small quantities. In private household use, it would be enough to fill a half to whole shell with some paper and light it. In industrial use, the shells can serve as an additive for fuels such as coal briquettes.

Besides being used as a cleaning agent or fuel, the shells can also be used in the food industry. Like the kernel, they have a nutty flavor and can flavor sauces and soups, for example. Because of the bitter substances they contain, however, they should be used in small quantities so that the end product does not acquire a bitter aftertaste.

The different use cases listed above clearly show that there are already many uses for walnut shells and that it is worth passing them on to other industries instead of disposing of them. With every raw material that gets a new use, we reduce waste and move further into a more sustainable future. We at LEROMA want to be a part of this movement by providing a market for waste materials through our surplus exchange.

Let’s simplify the future of change!