Insects: The sustainable superfood from Asia

Insects as food? Many Germans still can't imagine that, although the trend has been around for a long time.

This week, we've taken a look at the new superfood and invite you to dive into the topic with us:

There are around 2000 edible insects, some of which are a natural part of the diet in Asia, South America, Australia and Africa. Buffalo worms, grasshoppers, mealworms, crickets, ants, beetles, caterpillars and many more are an important source of nutrients in some of these countries, mainly because of the proteins they contain. These insects feel very comfortable in warm countries and reproduce strongly, which is why they are continuously available in large quantities. The same diversity is not found in cold European countries, but interest in insects as food is growing and even in Germany a few insect products are already available in stores.

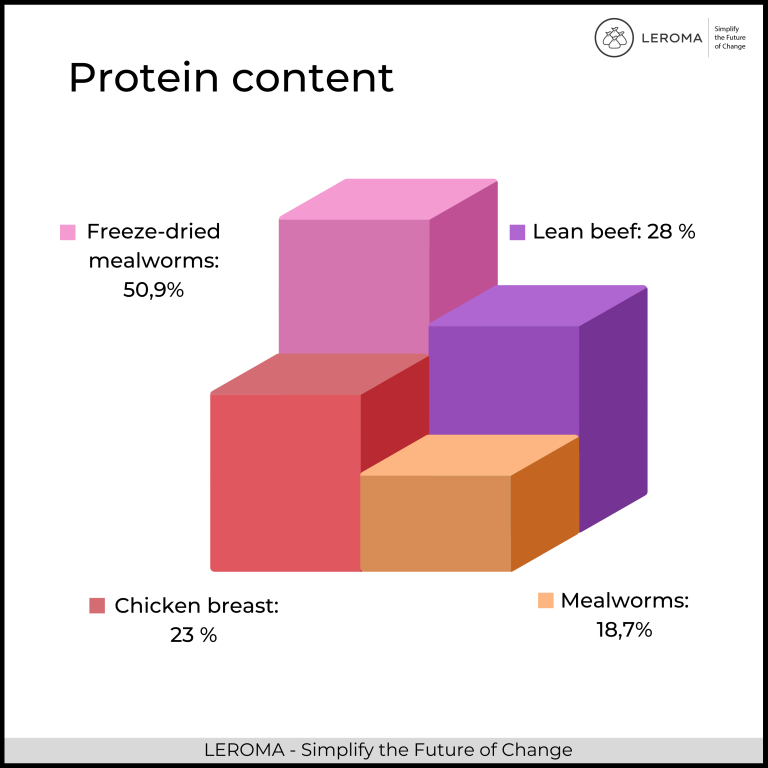

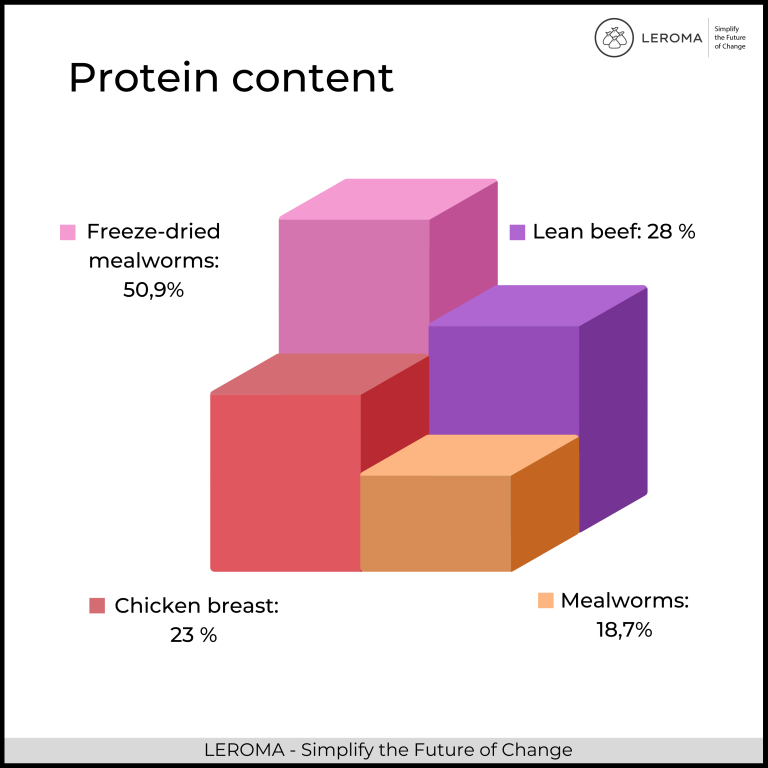

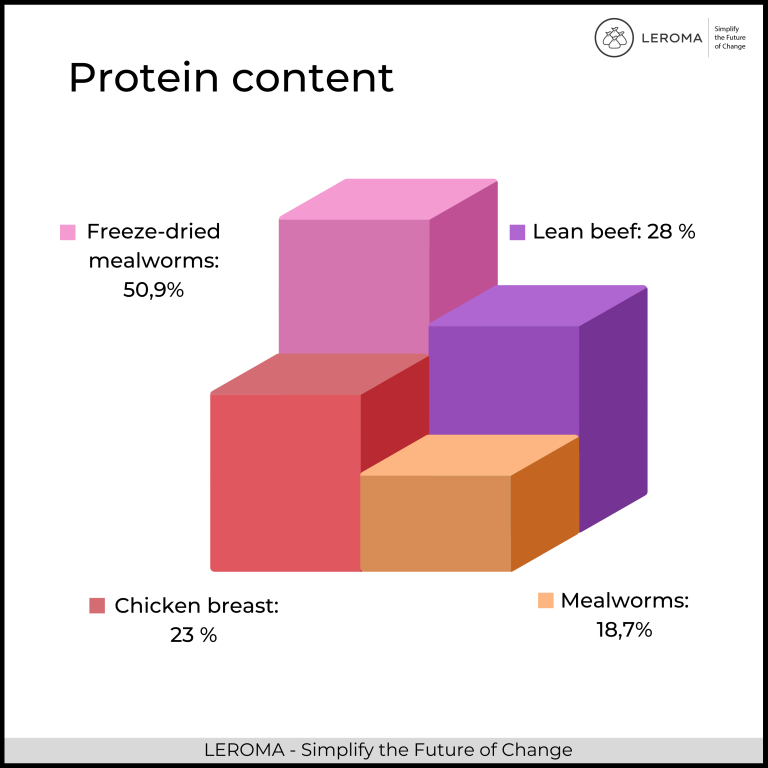

The small animals gain attention especially because of the high protein content, because edible insects contain on average between 35 and 61% protein. By comparison, beef, pork and chicken contain 22-27% protein. In addition, insects are rich in minerals, trace elements such as iron, zinc and vitamin B, and they have a high fat content. The fat content is balanced between saturated and unsaturated fatty acids, which include valuable omega-3 fatty acids.

Because of the ingredients, mealworms are processed into protein bars or powders for athletes, among others. It is interesting to note that the protein and fat content of insects increases significantly when they are freeze-dried, as water is removed from them during this process. For example, the protein content of mealworms increases from 18.7% to 50.9%.

The exact percentage of protein and other ingredients varies depending on the insect. In addition, the feed, development stage, habitat and processing also have an influence on the nutrient composition and taste. These factors must therefore be taken into account when breeding insects.

Insect breeding

Insects are an inexhaustible resource that could serve as a substitute for beef, pork or chicken in the future due to their ingredients. In addition, their breeding can be made more sustainable than that of larger farm animals.

To ensure high quality, they are bred in insect farms. There, they are grown in trays that can be stacked vertically on top of each other, saving an enormous amount of space. This type of cultivation is called "vertical farming." The term describes the production of plant and animal products in layers stacked on top of each other, for example, in order to be able to grow food such as fruit, vegetables and

algae within cities in a space-saving manner. Several thousand animals can be grown on individual trays, because insects like it cramped and dark.

They also need heat because they are cold-blooded and take on the ambient temperature. Critics see a problem here, because in Germany and many other European countries, insect farms would have to be heated for several months. For example, buffalo worms are bred at constant temperatures of about 30 °C. In return, they grow to the desired size in a very short time, even with little food, because they do not have to expend energy to regulate their body temperature. Buffalo worms need just 4 weeks for the growth process. The feeding efficiency of insects is particularly evident when compared with cattle. One kilogram of insect mass requires 2 kilograms of feed, while one kilogram of beef requires four times that amount.

In addition, the production of insects can be integrated into the circular economy if the small animals are fed with plant food residues, for example. However, insects should not be fed simply with waste, because in this case hygienic safety cannot be ensured. Therefore, it is not recommended to consume insects caught by oneself or to use them for the production of food. The recommended insects from breeding farms are called "edible insects" because they are bred especially for human consumption under hygienic conditions and thus can be consumed without any concerns.

Insects not only consume less feed, but also far less water than conventional livestock such as cattle. While eight liters of water are used to produce one kilogram of insect mass, the production of one kilogram of beef requires nearly 20,000 liters of water.

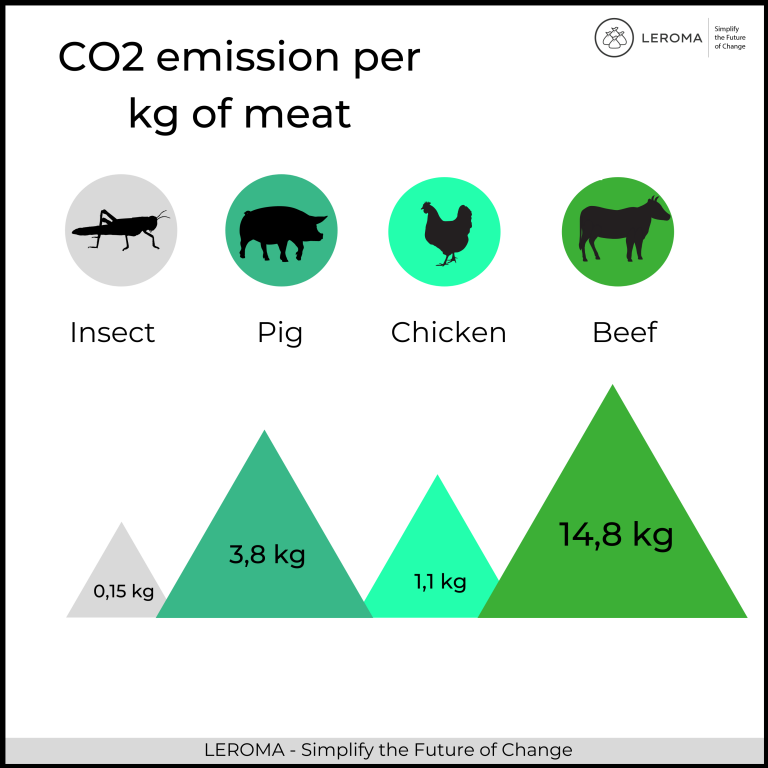

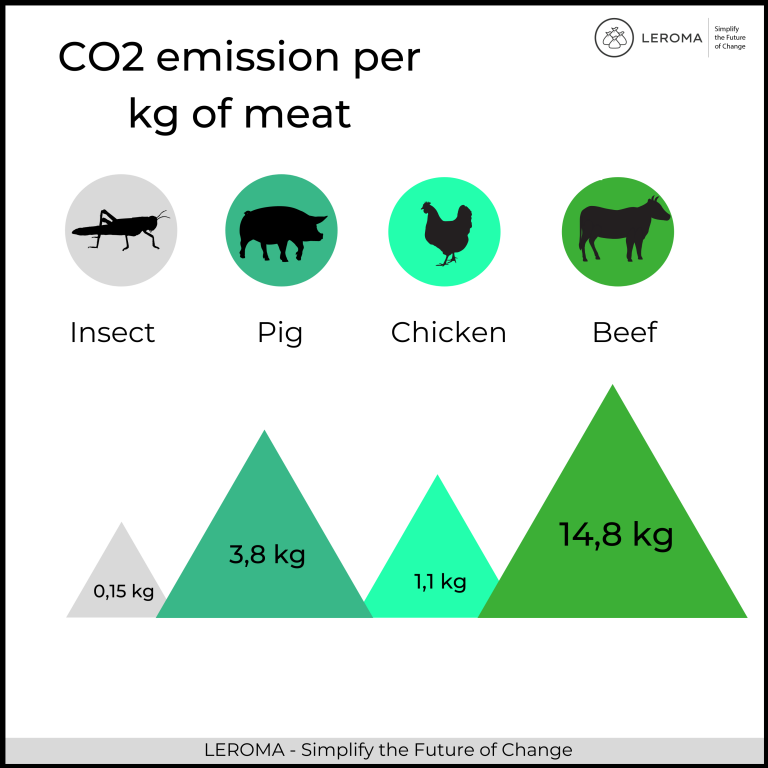

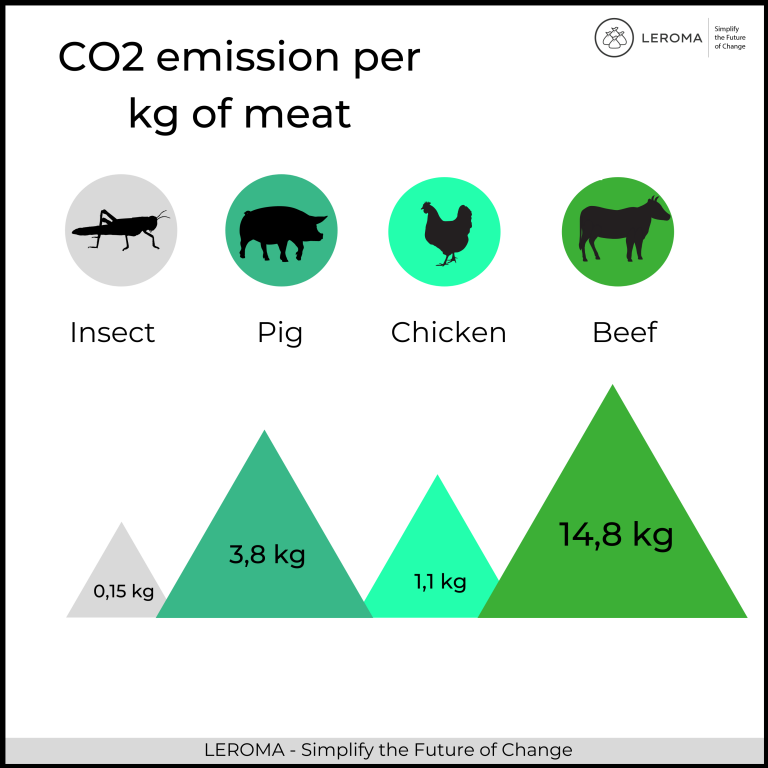

80 to 100 percent of insects can be consumed, making the edible portion almost twice as high as in cattle, where it is 50 percent. On top of that, insects produce significantly less greenhouse gases than conventional livestock such as pigs, which produce 10 to 100 times as much emissions as the same mass of mealworms.

Killing the insects

24 hours before the insects are killed for further processing, they are not given any more food to ensure that the gut is empty. This prevents contamination of the end product by any stomach and intestinal contents. At low temperatures, the cold-blooded insects fall into a kind of hibernation, during which all bodily functions are drastically reduced. In nature, this often happens at night when temperatures drop, while in insect farms this state is artificially induced. During breeding, the insects are cooled down so much that they no longer wake up. They are then cleaned and freeze-dried or otherwise processed. Although insects can perceive pain stimuli, they are probably not aware of the pain because they do not have a central nervous system. In general, killing insects by artificial hibernation appears to be much better than slaughtering conventional livestock.

There are also certified organic insect foods that, like conventional organic products, are characterized by certified organic, GMO-free feed, species-appropriate husbandry and the absence of auxiliary substances. This means that the small animals are provided with sufficient space, light and opportunities for movement.

Since insects do not need antibiotics or hormones in the first place, conventional insect breeding also does without them. This is because insects are hardly susceptible to diseases and are fed only high-quality food in closed breeding stations. By comparison, conventionally bred pigs are treated with antibiotics six times a year.

Insects as food in Europe

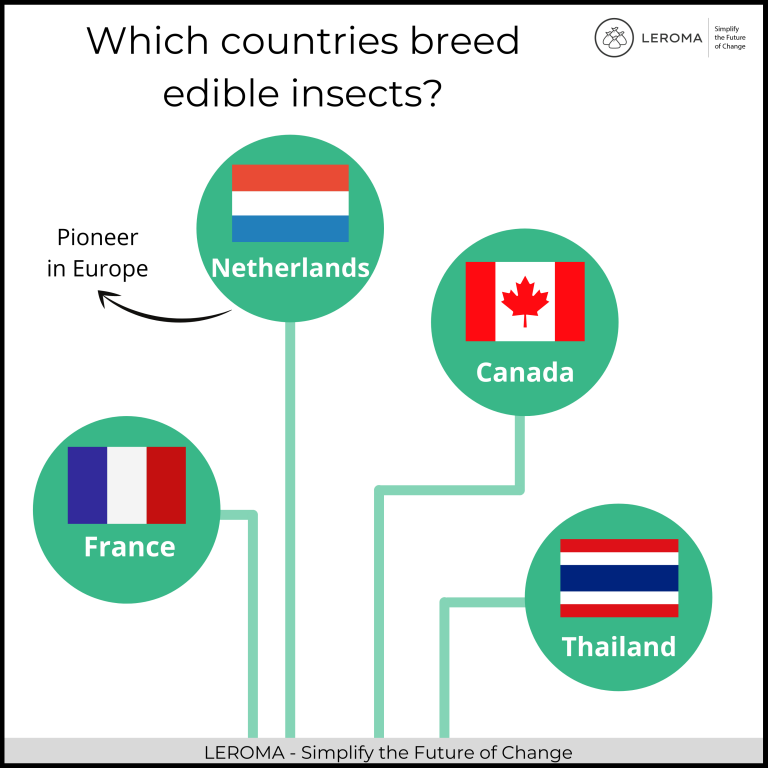

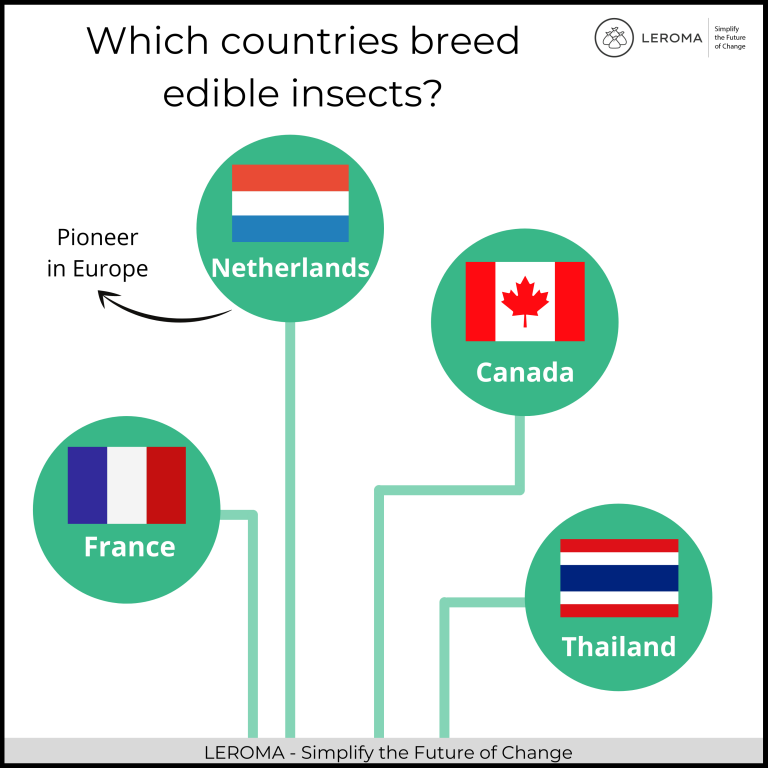

Since January 1, 2018, the sale of insects as food has also been permitted in Europe and there are now insect farms in the Netherlands, France, Spain and Canada, among other countries. In Switzerland, mealworms, crickets and grasshoppers have already been permitted as food since 2017.

Insect farms have only been permitted in Germany since 2020; until then, the protein-containing animals were imported from other EU countries and still also from Asian countries such as Thailand, where the consumption of insects has long been common.

In principle, there is currently a lack of uniform regulations for insect farming in Europe, because insects as food are still relatively new in our part of the world. Among other things, there are as of now no clear requirements for the approval of insect farms and processing plants or for identity labels to convey that producers of insect products adhere to certain hygienic measures.

However, the first EU-wide organic insect farming law was passed in 2019, defining husbandry and killing guidelines for seven species of beetles, flies and grasshoppers. Feed should be mainly organic and plant by-products and food processing residues, so that insects do not compete with human or animal diets.

Furthermore, hygiene requirements and species-appropriate husbandry conditions, which specify, among other things, how closely the small animals may live together and prohibit mutilations, must be followed. Finally, the law also specifies that the insects should be killed as gently and quickly as possible by placing them in hibernation on breeding farms. Killing methods such as slow desiccation in the sun are prohibited.

Insect products in Germany

Grilled, deep-fried or chocolate-coated grasshoppers and beetles are not an uncommon sight in Asia and are consumed as snacks without hesitation. Consumers do not shy away from the creepy-crawlies because they have been exposed to insects as food since they were children. In Germany, consumers usually react to the trend with disgust. For this reason, insects have so far mainly been sold processed into end products such as protein bars, burger patties or flour, although the small animals can also be found online whole, deep-fried or chocolate-coated. In fact, there are now restaurants in Germany that offer insect burgers with patties made from buffalo worms or even whole buffalo worms and grasshoppers to try.

In addition, one German bakery is already selling bread made from insect flour. This consists of ground mealworms and differs from conventional flours in its solubility, elasticity and water-binding capacity. Researchers are addressing this challenge to adapt the taste, baking properties and texture of insect flour to conventional flours to increase consumer acceptance.

Insects are also being used in animal feed to replace less sustainable sources of protein, such as soy or fish meal, but critics complain that this adds an extra step to the process and produces more greenhouse gases than if the feed spent on the insects were fed directly to the larger farm animals.

Labelling of insect

Because consumers are not used to insects as food, companies have to inform their customers about possible dangers, since the packaging of the novel products still often lacks information on how they should be used. For example, some of them need to be heated before consumption to kill any germs or improve digestibility. It is particularly important that insect content is clearly labeled in the ingredient list, as it can cause allergic reactions, even if the risk is considered to be rather low. Nevertheless, consumers who react to crustaceans may also show allergic symptoms to chitin, the body shell of some insects. The protein tropomyosin or the feed, for example soy or wheat, may also cause reactions in allergic individuals. So the mostly imperfect labeling of ingredients can be quite problematic and should be carefully revised in the future.

Interest in edible insects is growing, but for the time being the little animals remain a niche product because they have so far been very expensive. For example, the price of one kilogram of insect meal is around 100 euros, while the same amount of conventional meal usually costs no more than one euro, and 70 grams of mealworms cost just under eight euros. The reason for this is the still relatively complex manual breeding process. In the future, however, prices could fall sharply if the production process for insect foods is industrialized.

Insects are also used in other industries. An active ingredient is already being extracted from wound maggots for use in ointments, plasters and wound dressings to significantly accelerate the healing of inflamed tissue, for example.

The small animals are therefore not only a resource-saving source of nutrients but also an innovative raw material for alternative industries, which is currently gaining more and more recognition and will soon be clearly visible on the market.

Let’s simplify the future of change!