Why fish heads, bones and scales are too good for the bin

Fish is an important part of the human diet worldwide and was already on the menu of the Neanderthals. The marine animals are a valuable source of nutrients, because they provide easily digestible proteins, vitamins, trace elements and healthy unsaturated fatty acids. Trace elements include iodine, which is essential for our metabolism and organism.

Edible fish that are suitable for consumption, end up on the plate of every second German at least once a week, and for every fourth even twice. In 2020, per capita consumption in Germany was around 13 kilograms, while the global average was 20 kilograms. This corresponds to 154.2 million tons of fish consumed worldwide last year.

The steady rise in consumption results in more than half of global fish stocks being overfished, i.e. more fish are caught than are added through natural reproduction. Unfortunately, despite these alarming developments, this valuable resource is not being fully exploited. Every year, ten million tons of fish are thrown back into the sea, mostly dead or dying.

The reason for this is the bycatch and "high grading". The bycatch are fish and marine animals that are not the actual fishing target, but are nevertheless caught in the nets. This bycatch can only be partially utilized, the rest is usually discarded severely injured. In 2013, the EU enacted a discard ban to encourage fishermen to use selective fishing techniques to avoid pulling so many unwanted marine animals onto their vessels in the first place.

Selective fishing techniques can include acoustic signals designed to deter dolphins, for example, hooks shaped and fastened differently so fewer seabirds get tangled in them, or more specialized baits that are less attractive to sea turtles.

But it's not just unwanted fish that pose a challenge, but also plastic waste, which accounts for 10 to 30% of bycatch worldwide. To avoid the time-consuming storage and costly disposal, this is also thrown back into the sea. Some environmental organizations want to encourage fishermen to hand in the trash at ports and therefore now accept it free of charge.

.png)

But "high-grading" is also a big problem. Fishermen throw high-value fish into the sea to fill their holds instead with larger specimens and more popular fish species that bring in more money. This practice has been banned since 2009, but can be difficult to control. In some cases, the fish are stockpiled and thrown overboard after inspection. Dead.

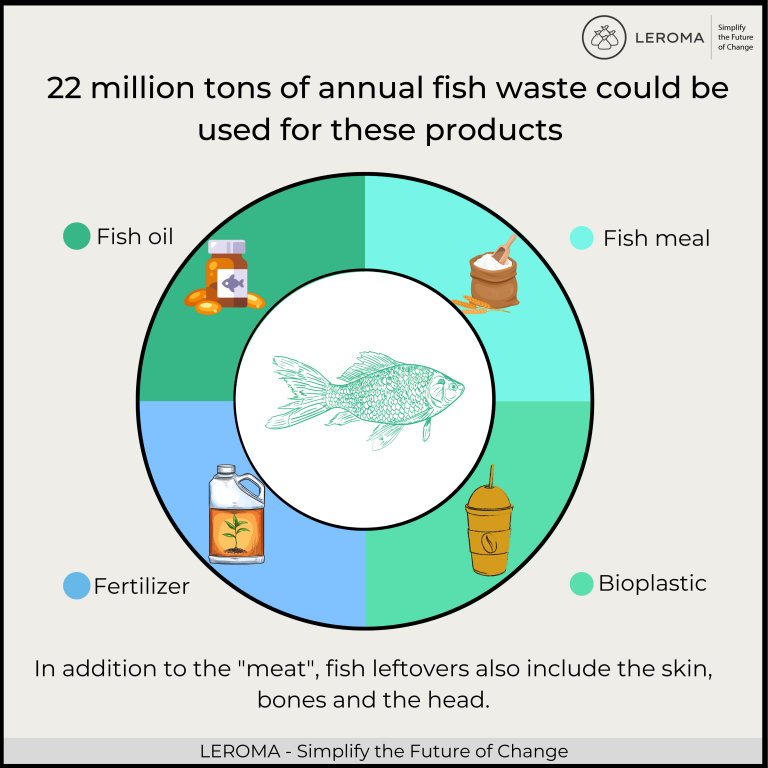

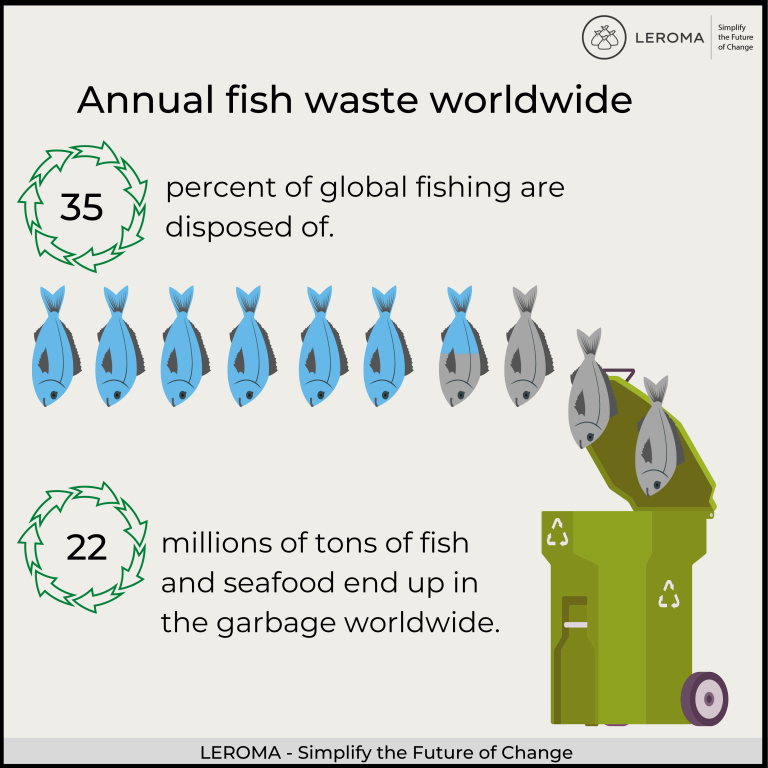

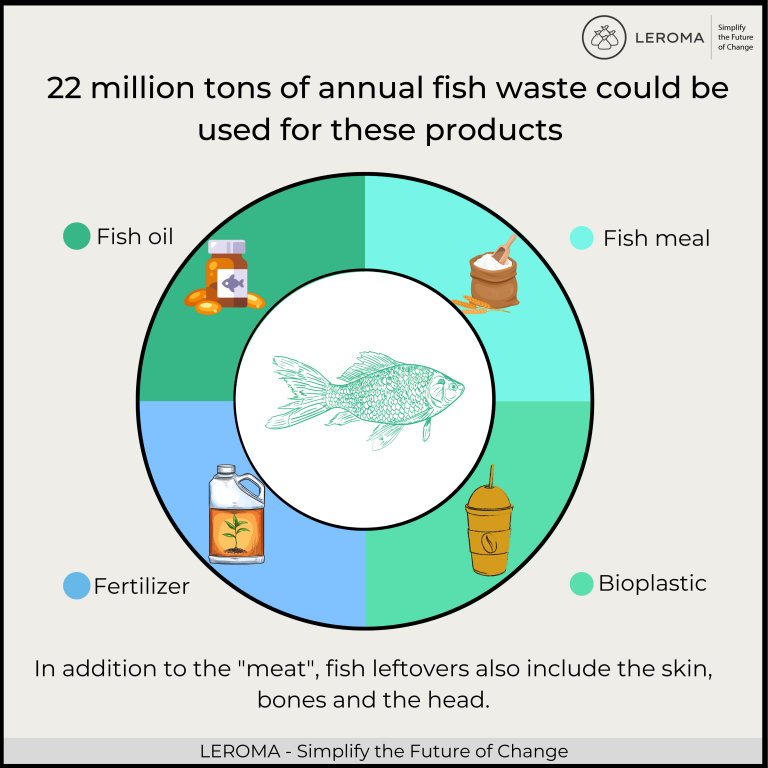

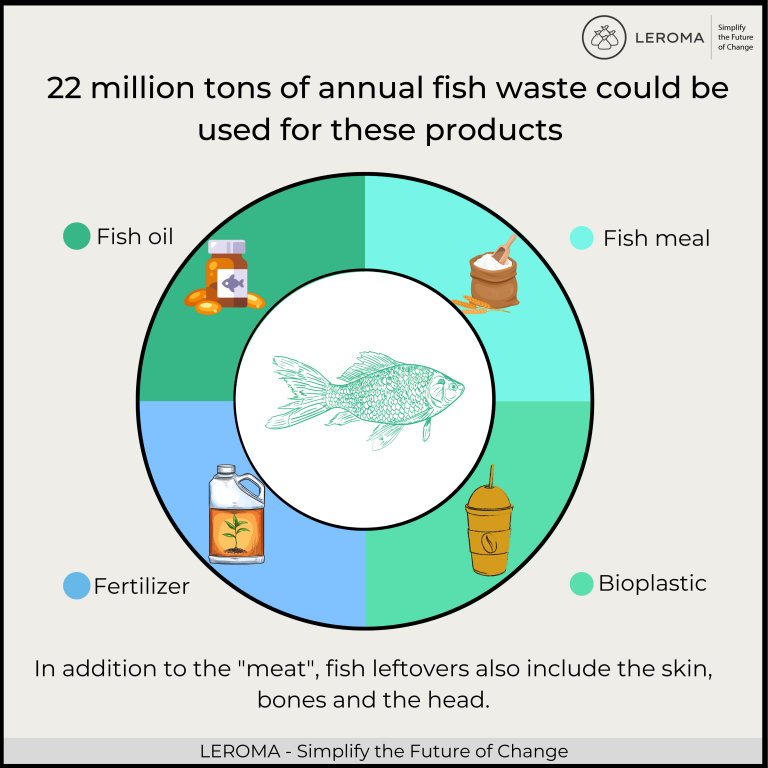

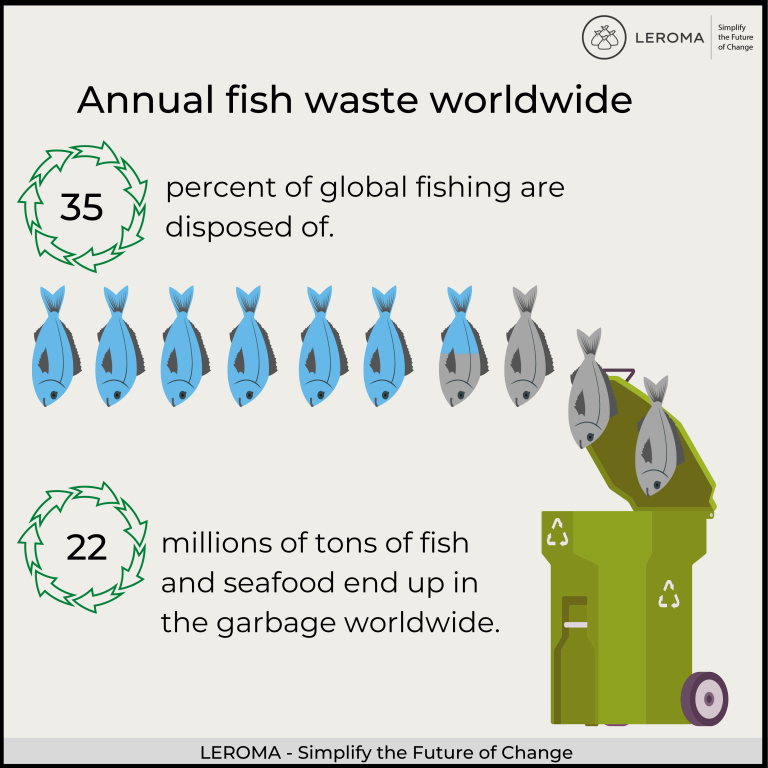

In addition, even fish that reach our ports are discarded because they do not keep long raw and spoil before they can be made available to consumers. So, every year, 35% of the fish and seafood caught worldwide, 22 million tons, are lost unused for various reasons. In addition, offal such as the skin and bones are often not utilized even though they are a useful resource.

Possible uses of fish scraps

When fish are processed into fillets, for example, the heads end up in the garbage can first, although they still contain many pieces of meat that can be added to soups and ragout, among other things. The heads and other scraps left over from filleting can be used to make farce; a mass of chopped or ground fish that can be used, for example, to stuff vegetables and meat or formed into dumplings to add to soups.

Fish heads can also be boiled together with the skin and even the bones. The decoction produced is called fish stock and serves as a basis for fish soups or sauces for dishes with fish or other sea animals and seafood. The taste varies from strong, spicy to mild depending on the type of fish used. Fatty fish such as mackerel, herring or salmon, in which the fat content is more than 10%, are not suitable for this purpose, because the fat gives the stock an unpleasant aftertaste.

For many years now, fish waste, which mainly includes offal but also whole fish, has been used primarily for the production of fish meal and fish oil. Thus, a process already exists on the market that uses the small, less marketable fish that are discarded during high-grading. In coastal regions, crustaceans, starfish or mussels from the bycatch are also used.

Fishmeal

Around 15 million tons, most of the fish caught that is not processed for human consumption is used for the production of fishmeal, but in addition, certain fish species are caught specifically for the extraction of the meal, while surpluses and leftovers end up in large quantities in tons and our oceans. Increased use of these residues can increase the sustainability of production. Currently, 54% of fishmeal in Europe consists of by-products.

Fishmeal is mainly used as feed for farm animals or pets. It contains easily digestible proteins, essential amino acids and, like all fish products, omega-3 fatty acids, which are healthy and vital because they affect the flow and coagulation of blood, have an anti-inflammatory effect and have a positive influence on metabolism. The omega-3 is absorbed by the fish through

microalgae on which they feed.

Fishmeal is also fed in aquacultures where food fish are raised, usually in the form of pellets, although it is now often replaced by vegetable proteins, usually mimicking the amino acid composition of fishmeal by combining different ingredients. The world's largest producers of fishmeal and oil are Chile, Peru due to its large and coastal fish stocks, Denmark, Norway and Panama.

Fish oil

Due to its high content of omega-3 fatty acids, fish oil is mainly sold as a dietary supplement in the form of capsules. Humans cannot produce the essential fatty acids themselves, but must take them in through food. The oil is also said to have a positive effect on cardiovascular diseases, but to date no medical benefit has been proven with certainty.

Depending on the type of fish used, the content of the omega-3 fatty acids EPA (eicosapentaenoic acid) and DHA (docosahexaenoic acid) varies. DHA is important for metabolism and is found primarily in the brain and retina, as the fatty acid is an essential component of the membranes of nerve cells, for example. EPA plays a role above all in the regulation of blood pressure and heart rate. The most suitable fish for the production of fish oil are fatty fish, whose tissues contain more oil than those of lean fish.

Production process of fish meal and oil

The production of meal and oil usually goes hand in hand, as a separation process is used to separate the solids and liquids from the fish and process them into the respective products. The production process consists of three steps, and it makes no difference whether whole fish or only parts of it are used. The first step is the thermal treatment, in which the materials are heated to a temperature between 85 and 95°C in order to kill any existing germs. In addition, the components decompose and the proteins denature, which means that their structure changes, but their chemical properties remain unchanged. The process results in the release of the contained oil.

The solid and liquid components are then separated, for example with a screw press, which is also used for sludge dewatering. Alternatively, the substances can also be separated from each other by pressing or centrifugation. Centrifugation does not require high temperatures, but the solids contain a higher residual moisture in return. Which process is used depends, among other things, on how much raw material is to be processed.

Two liquids are produced in this step; an oily substance, the fish oil, and the so-called "stickwater", which may still contain fine solids and is rich in proteins and iodine. The stickwater can be evaporated and added to the solids, which are then dried in the third and final step. Again, there are different methods that can be used and significantly affect the quality of the final product.

The higher the temperature at which the solid ingredients are dried, the lower the quality of the resulting fish meal, as the protein content is reduced by the heat. For this reason, the ingredients are often dried in a rotating drum into which heated air is blown, since temperatures are higher when heated directly, for example by a gas burner.

The dry mass is finally ground. Depending on the drying process, the finished fish meal has a protein content of between 62 and 73% and usually a residual moisture content of less than 10%. With the production process presented, all fish residues can be fully utilized.

Fish Protein Hydrolysate (FHP)

In addition to flour or oil, fish protein hydrolysate can also be produced from whole fish or parts thereof. For this purpose, the proteins contained are hydrolyzed, i.e. they are split into amino acids by a reaction with water. FHP is said to have antioxidativ or other enhanced functional properties. The simplest form of FHP is liquid and contains up to 90% moisture. However, it cannot be stored for long in this state and is difficult to transport. Therefore, dried, powdered FHP is preferred, but its production is often energy-intensive and expensive.

The protein hydrolysate can serve as a source of protein for human consumption or be used as fertilizer. Unlike artificial fertilizer, it does not contain pollutants that could remain in the soil. In addition, almost 100% of the fish is utilized in the production of FHP, which is why most of the essential nutrients are retained and available to plants.

In addition, FHP is also used as a cryoprotectant for fish. Cryoprotectants are an adjuvant that can be added during freezing to stabilize the raw material and prevent it from losing its effectiveness. A relatively new process can even be used to produce a

biodegradable plastic from fish skins and scales that can completely decompose in less than six weeks.

The examples listed show that fish scraps and surpluses do not equal waste and can be used innovatively in various industries. We are particularly interested in this topic because within the Lowinfood project, LEROMA was primarily divided into the two work packages dealing with the food categories of fruits and vegetables and fish. In the next years we would like to demonstrate how the loss of these raw materials can be reduced with the help of our surplus exchange.

Let’s simplify the future of change!

.png)

.png)